Digital dashboards that help you identify deviations and make the right decisions.

Capture your deviations and turn them into improvements

Continuous improvement, Kaizen boards, PDCA and other tools.

All your team’s tasks, neatly organized in one weekly view.

Improve key performance indicators within your specific focus areas with our SQCDP board.

Use the PDCA cycle as a tool to improve both quality and processes

Digital tools for 5S work, recurring audits, and a well-organized workplace.

Visualize KPIs and communicate effectively throughout the entire organization.

Basic project management and activity boards.

Kanban is a powerful method for visualizing, managing, and optimizing workflows.

Digital dashboards for takt time flow with takt time counter and stop time log.

Digital visitor registration provides full control over all planned and executed visits to your business.

Tired of time-consuming manual routines, double data entry, and the challenge of keeping track of your workflows? Then Boards on Fire’s digital daily management tool is the solution, offering clear deviation handling and smart follow-up that drives continuous improvement.

To build efficient and well-functioning work processes, organizations need not only to plan and manage at an overall level, but also have a structured way to follow up and improve the work carried out day to day. This is often referred to as daily management.

Below are five reasons why you should implement digital daily management with Boards on Fire.

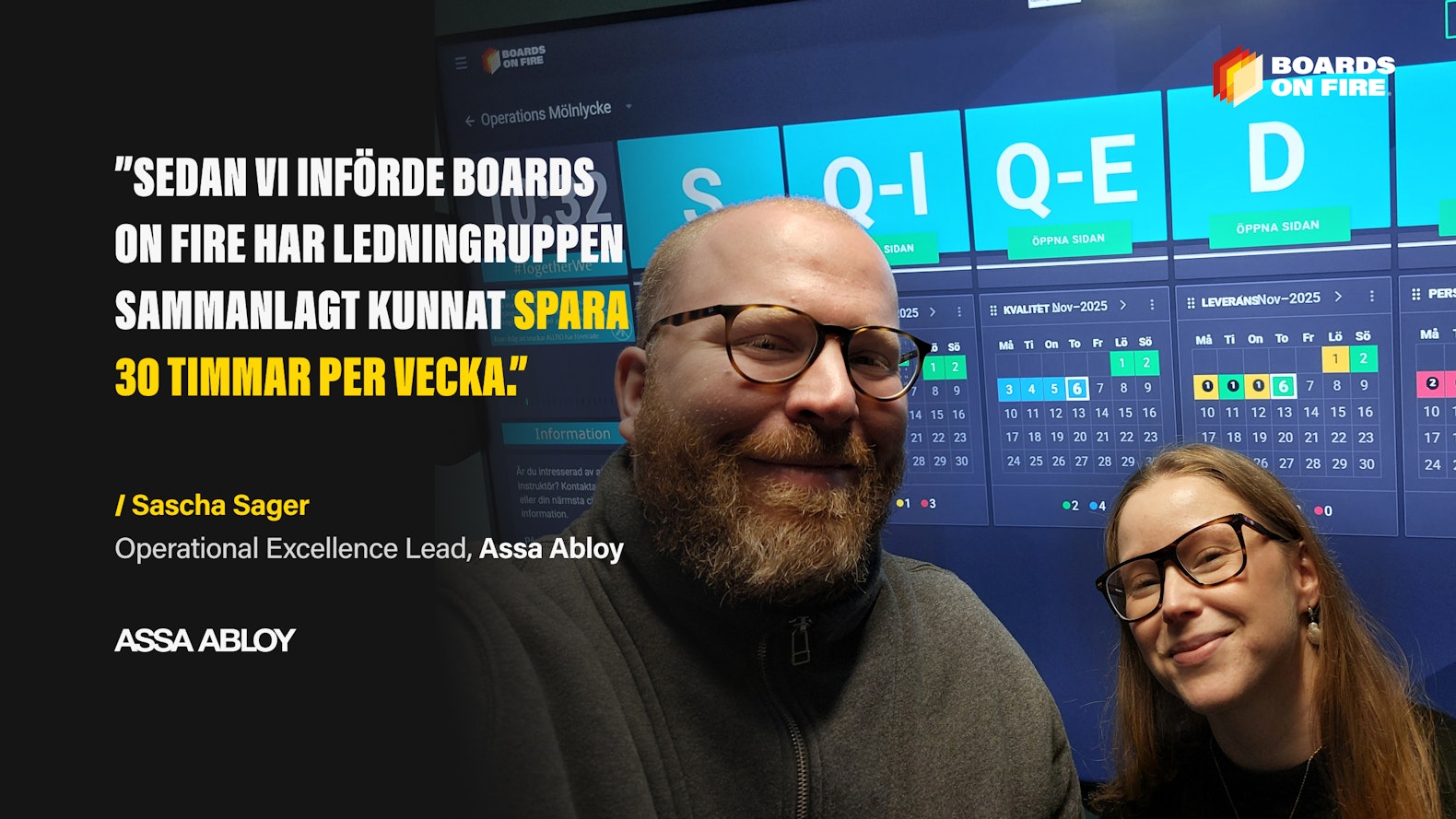

Analog boards can be visually clear, but they often limit efficiency. Double data entry and information that fails to reach the right person at the right time are common issues. With Boards on Fire, all information is gathered in one place, providing a clear and shared overview. For example, Assa Abloy in Mölnlycke has saved three hours per week per team leader, amounting to a total of 30 hours.

With digital daily management in Boards on Fire, decisions can be made quickly and collaboration becomes more effective. All information is automatically collected in the system, offering full visibility into both historical and real-time data. Production managers and team members no longer need to waste time searching for information. Acting on the same facts becomes easy, strengthening collaboration and boosting productivity.

In Boards on Fire, it is easy to identify, manage, and follow up on deviations. The deviation module is a very popular feature among our users and has, among other things, resulted in reduced downtime, clearer responsibilities, and more actions taken. Take photos, delegate the task to the right person, and set clear deadlines. Everything is carefully documented—nothing gets lost—and the team can then turn deviations into concrete actions that can be visualized for the entire team.

For example, Bruzaholms has doubled the efficiency of their deviation management, freeing up time that can instead be spent on driving improvements.

In organizations that still rely on analog daily management, improvement suggestions often stall or get forgotten, frequently ending up in a “suggestion box” with no follow-up. With Boards on Fire’s improvement module, your team can easily capture suggestions, which are then tracked and followed up. Ongoing activities are displayed on the pulse board with due dates, making deadlines and progress easy to monitor. New activities can be created directly during the daily meeting, complete with a name, description, responsible person, labels, files, and images.

Many of our users report that this boosts team morale and creates a sense that the suggestions and issues raised are truly taken seriously and properly addressed.

Structured and consistent work is key to an efficient and safe work environment. Clear routines and standards help reduce waste, avoid mistakes, and support smooth collaboration. In Boards on Fire, you can create dashboards that structure work across the entire organization, for example linked to improvement work, deviations, or daily routines.

Daily management, also known as "daily gemba," is an important principle in lean production. It focuses on continuously improving workflows by identifying and addressing problems and obstacles, which involves being present each day where actual production takes place to continuously enhance the process.

Daily management can be carried out in several ways, such as through daily team meetings where issues and improvement suggestions are discussed, or by using visualization tools like Kanban boards to track workflows and identify potential bottlenecks.

1. How does Boards on Fire work on different devices, and can we use it remotely?

Boards on Fire is a responsive, cloud-based solution, which means the boards automatically adapt to the device you are using. The tool is accessible wherever you are, as long as you have an internet connection. Whether you are using a smartphone, tablet, computer, or an 85-inch TV, Boards on Fire works seamlessly.

2. How much does Boards on Fire cost?

Boards on Fire offers four pricing plans, Basic, Premium, Pro, and Enterprise, tailored to the size and needs of your organization. The cost varies depending on the features and scale that best fit your requirements.

Contact our sales team to find the package that’s right for your organization.

3. Is it possible to integrate with Boards on Fire?

Yes, absolutely and it doesn’t have to be complicated. As long as your data is accessible, it can be imported and visualized in Boards on Fire. This can include data from ERP, CRM, MES, PLM, production systems, management systems, machinery, or other sources. Read more about integrations here.

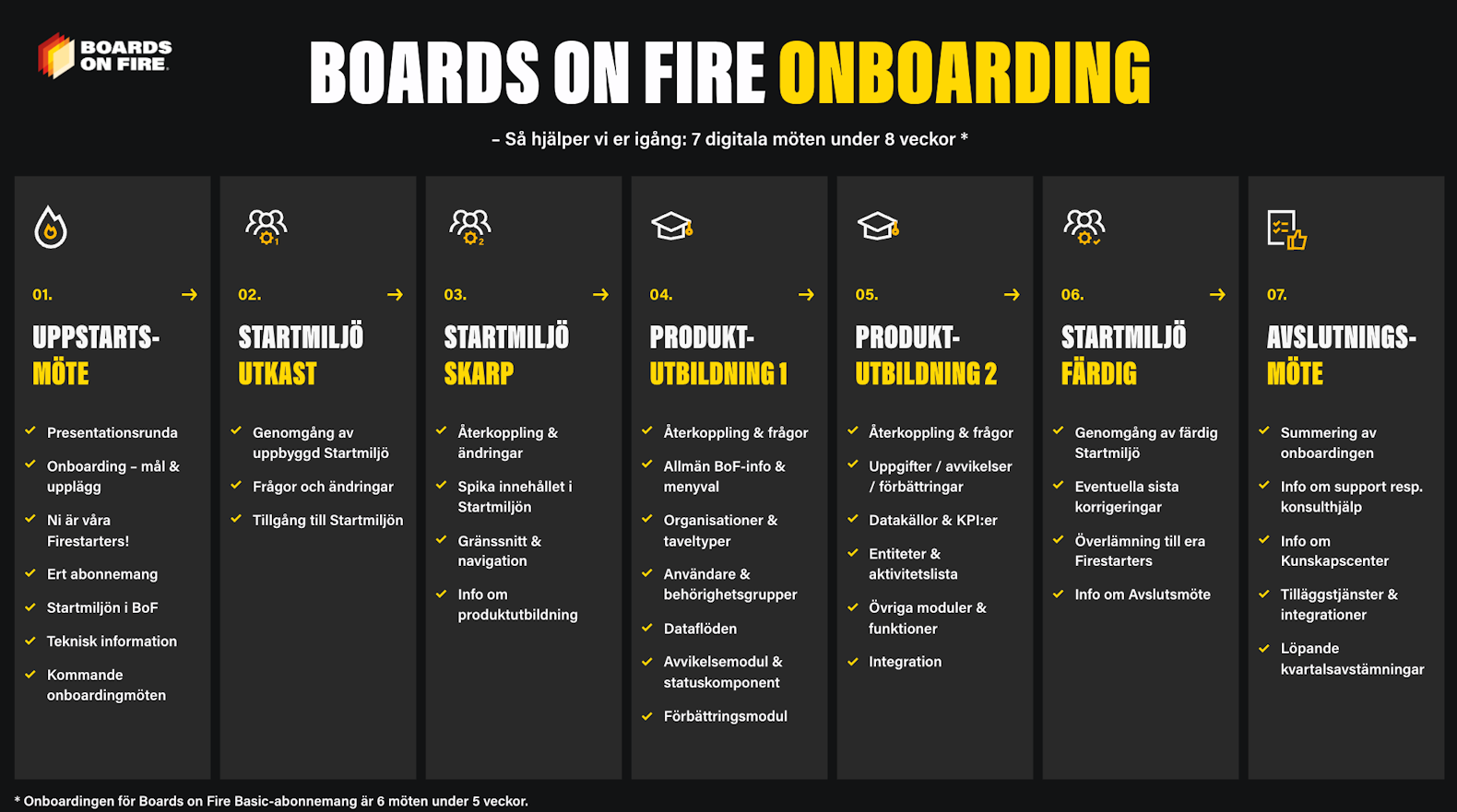

4. How does implementation of Boards on Fire work?

To ensure a smooth start, we always provide digital onboarding with training and the creation of your digital boards, guided by a dedicated Customer Success Manager. Please note that each organization is responsible for its own screens and hardware; we do not supply or install hardware on-site.

Happens at Boards on Fire

Free web demo