Digital dashboards that help you identify deviations and make the right decisions.

Capture your deviations and turn them into improvements

Continuous improvement, Kaizen boards, PDCA and other tools.

All your team’s tasks, neatly organized in one weekly view.

Improve key performance indicators within your specific focus areas with our SQCDP board.

Use the PDCA cycle as a tool to improve both quality and processes

Digital tools for 5S work, recurring audits, and a well-organized workplace.

Visualize KPIs and communicate effectively throughout the entire organization.

Basic project management and activity boards.

Kanban is a powerful method for visualizing, managing, and optimizing workflows.

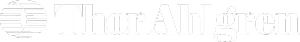

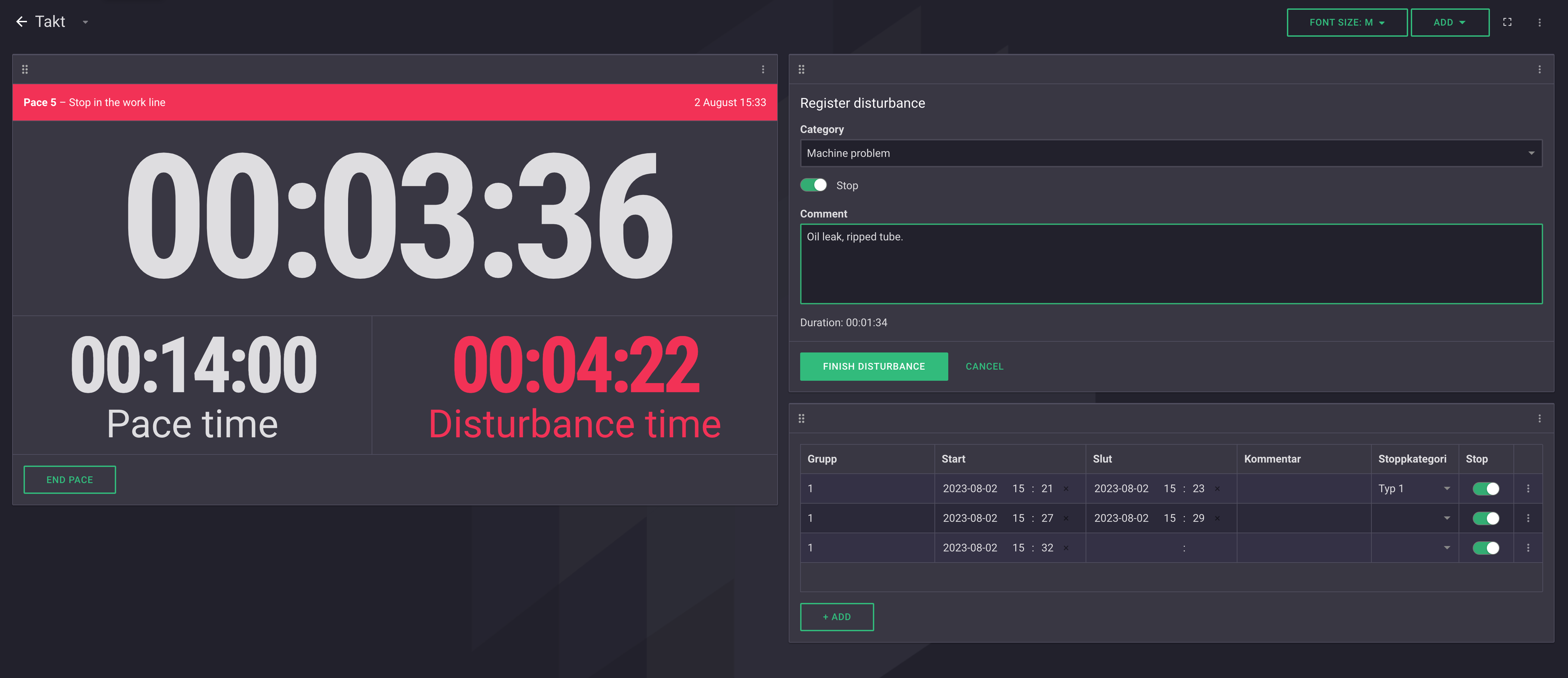

Digital dashboards for takt time flow with takt time counter and stop time log.

Digital visitor registration provides full control over all planned and executed visits to your business.

With Boards on Fire, you visualize takt time flow and register disturbances and stops. Our takt time dashboard with a takt time counter and downtime gives you a complete overview of the status in production. Book a free demo and we'll show you how!

Our solution for paced flow (or takt time flow) is very easy to get started with. The core is the takt time dashboard with the takt time counter showing the countdown on the current pace. There you also see the set takt time, registered downtime and clear color signals for the status in the production line. Green for ok, yellow for problems, and red for stops. Blue color is displayed during planned breaks.

Boards on Fire is a cloud service that you can use on virtually any internet-connected device that has a web browser. You can visualize the takt clock on large screens or smart TVs in production, but also log in on the computer, tablet or mobile.

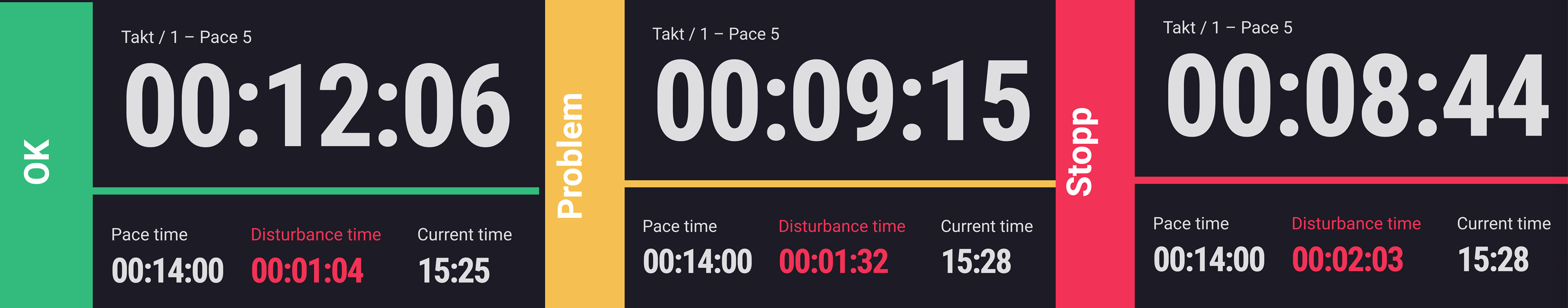

You easily input takt time and weekly schedule for production time day by day, with shifts, breaks and other planned pauses that control when and how your paced flow should run.

You can easily register, categorize and comment on disturbances and stops for different stations in the production line. All information is logged and saved in Boards on Fire for further follow-up. Registration of downtime and disturbances can also be used as a standalone solution without running takt time flow.

Free web demo

Using paced flow within the manufacturing industry can have several advantages that together contribute to a better and more cost-effective production process: