Digital dashboards that help you identify deviations and make the right decisions.

Capture your deviations and turn them into improvements

Continuous improvement, Kaizen boards, PDCA and other tools.

All your team’s tasks, neatly organized in one weekly view.

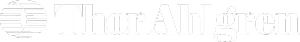

Improve key performance indicators within your specific focus areas with our SQCDP board.

Use the PDCA cycle as a tool to improve both quality and processes

Digital tools for 5S work, recurring audits, and a well-organized workplace.

Visualize KPIs and communicate effectively throughout the entire organization.

Basic project management and activity boards.

Kanban is a powerful method for visualizing, managing, and optimizing workflows.

Digital dashboards for takt time flow with takt time counter and stop time log.

Digital visitor registration provides full control over all planned and executed visits to your business.

Boards on Fire makes it easy to capture, record, and manage deviations. In the pursuit of a disturbance-free operation, we help you track both large and small deviations and turn them into improvements.

Our deviation module comes fully equipped with everything you need to manage deviations in all areas of your operations. With the connection to the improvement module, the entire flow from deviation to completed improvement is captured.

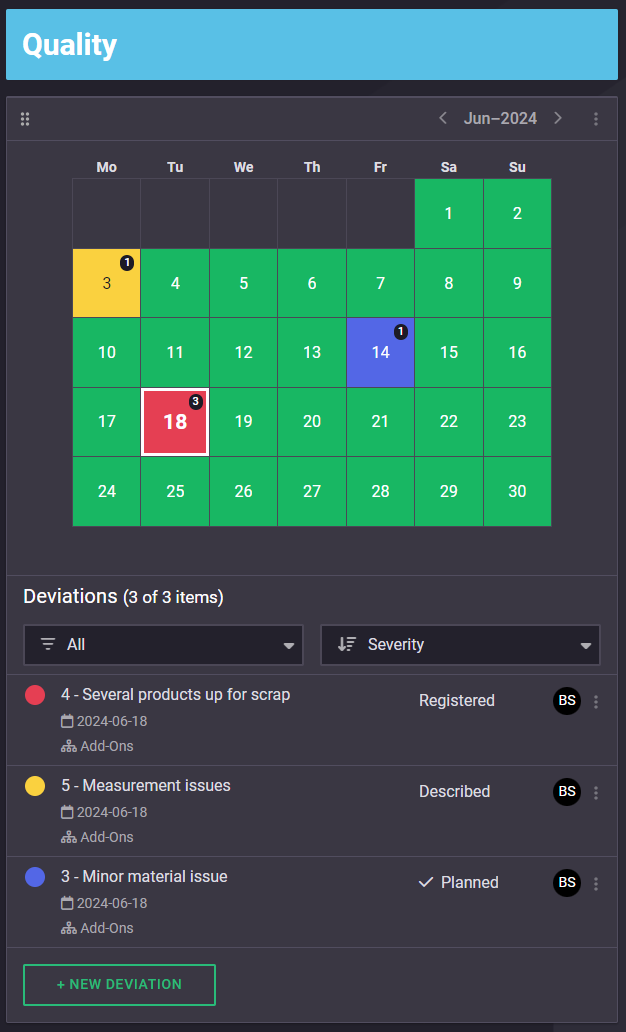

A disruption-free production is ‘the holy grail,’ and our solution helps you capture, analyze, and address all types of deviations, such as production issues, safety risks, or quality deficiencies. Deviations can be managed in several different views, such as the classic Green Cross, calendar view, or overview.

The system is flexible, and the deviation module can easily be connected to our improvement module and then adapted to both small and large deviations, allowing you to manage everything from 'quick fixes' to systematic actions using the PDCA method (Plan, Do, Check, Act). Following up on deviations provides you with valuable insights that help you implement the right actions and plan ahead. You’ll have a better basis for deciding where to focus and allocate resources for maximum impact.

An employee can quickly register a deviation via their mobile directly from the shop floor. After that, all involved parties can follow the progress in real-time. Once the deviation is addressed, it can be followed up with improvement suggestions that ensure the problem does not recur, contributing to continuous improvements.

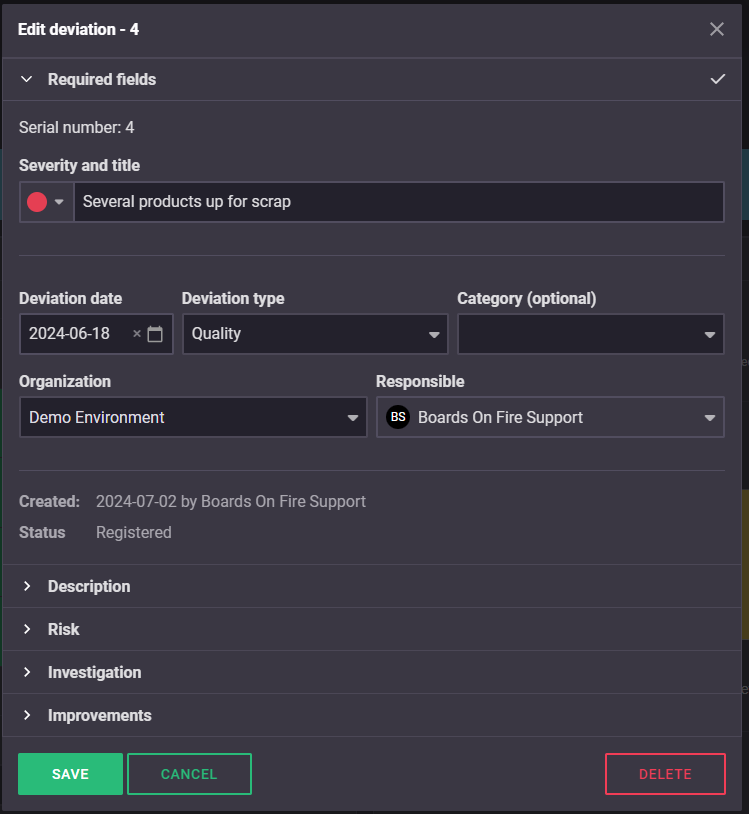

It’s easy to manage each deviation as a separate case—they are indexed and assigned a unique serial number. In doing so, it becomes simple to create and handle multiple deviations per day! Below is an example of three registered deviations from June 26.

Each deviation becomes an unique entry, they are also assigned a status depending on where you are in the process. This makes it easy to get an overview of your progress in managing them.

Free web demo

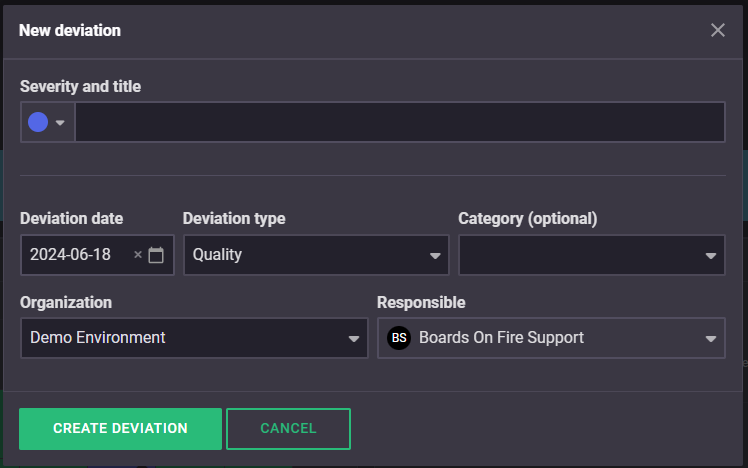

We have built this module with every step in mind. We want to capture all the organization’s deviations – and to do that, it needs to be easy to register them! That’s why the creation flow is very simple. Select the component that handles the type of deviation you want to register (e.g. Quality) and press '+ New Deviation'. Here, you only need to fill in a Severity level and a title – then the deviation can be created!

This can be done in about 10 seconds directly from a mobile device, on a PC or tablet.

After the deviation is created, you can continue working with it in a clear flow, as shown in the image below.

Now you can get the entire flow from deviation to completed improvement in Boards on Fire. Create a deviation based on a component in Boards on Fire, maybe a deviating key metric, and follow the entire deviation process. Then create improvement actions to ensure the deviation doesn't happen again! Everything is connected, and you can see the link between deviations and improvements.

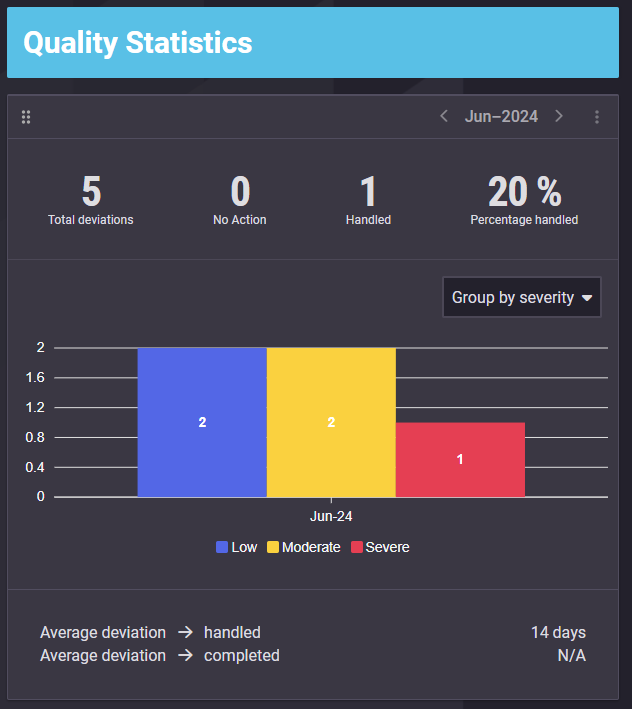

In addition to the deviation module, there is also a component for deviation statistics. Here, you can see how many deviations have been registered and managed. They can also be grouped in various ways.