Digital dashboards that help you identify deviations and make the right decisions.

Capture your deviations and turn them into improvements

Continuous improvement, Kaizen boards, PDCA and other tools.

All your team’s tasks, neatly organized in one weekly view.

Improve key performance indicators within your specific focus areas with our SQCDP board.

Use the PDCA cycle as a tool to improve both quality and processes

Digital tools for 5S work, recurring audits, and a well-organized workplace.

Visualize KPIs and communicate effectively throughout the entire organization.

Basic project management and activity boards.

Kanban is a powerful method for visualizing, managing, and optimizing workflows.

Digital dashboards for takt time flow with takt time counter and stop time log.

Digital visitor registration provides full control over all planned and executed visits to your business.

The bed and sofa manufacturer Scapa was one of the first industries to start using Boards on Fire's solutions fully in its operations. And it has paid off. Increased commitment, more implemented improvements and increased productivity are some of the benefits that factory manager Miika Porkola highlights.

Digital pulse meeting boards for daily management in combination with boards for continuous improvements and boards that visualize production in real time for employees in the business. These are some parts of the Boards on Fire set up in the factory with 75 employees in Alvesta, Sweden.

– In Alvesta, we manufacture beds, mainly for the Swedish market. But the plan is to grow in Europe, which we have both space and capacity to do. That journey has already begun little by little in the German market, says Miika Porkola.

Scapa also has five more factories with more than 700 employees in and around Kaunas in Lithuania. One plant is a direct subcontractor to Alvesta, one is focused on volume production for Ikea, two produce sofas and armchairs for the northern European market and the fifth is currently filled with mixed furniture production.

– Every morning, five different group meetings are held around the business and the information from the group boards in Boards on Fire automatically updates the pulse board for the production management, which holds its meeting a moment later. There we get an overview of how the factory is doing right now. We go through staffing, health and safety, production figures and logistics. We check the order intake and can make quick decisions about changes in the planning based on that information. We handle deviations, delegate daily activities and also get an overview of the improvement work, says Miika Porkola.

– There are many benefits. Previously, we had twice as long meetings with both poorer content and structure. With Boards on Fire, we have gathered everything in one place, we get better control and more efficient meetings. Employees can participate remotely if needed and it has become much easier to share information and delegate tasks. This has led to us now having more people who can, and above all want to, take responsibility. Simply put, increased commitment among all employees!

– More questions, more ideas, more improvement proposals and more implemented improvements. That's one side of it. Increased productivity is another. We have gone from a productivity of 56 percent a few years ago to today a rate of as much as 92 percent. Of course, there are many factors that come into play there, but Boards on Fire has definitely contributed strongly to that development, says Miika Porkola.

We have gone from a productivity of 56 percent a few years ago to today a rate of as much as 92 percent.

Another important aspect that Miika Porkola highlights is that as Boards on Fire has made it easier to delegate tasks and distribute responsibilities, production managers have more time for their staff. Listen, coach and develop on an individual level.

– We have also chosen to be very transparent and visualize the same information to all employees via Boards on Fire. Everything from the production rate for the various groups to financial key figures that show how things are actually going for the company. It has increased participation.

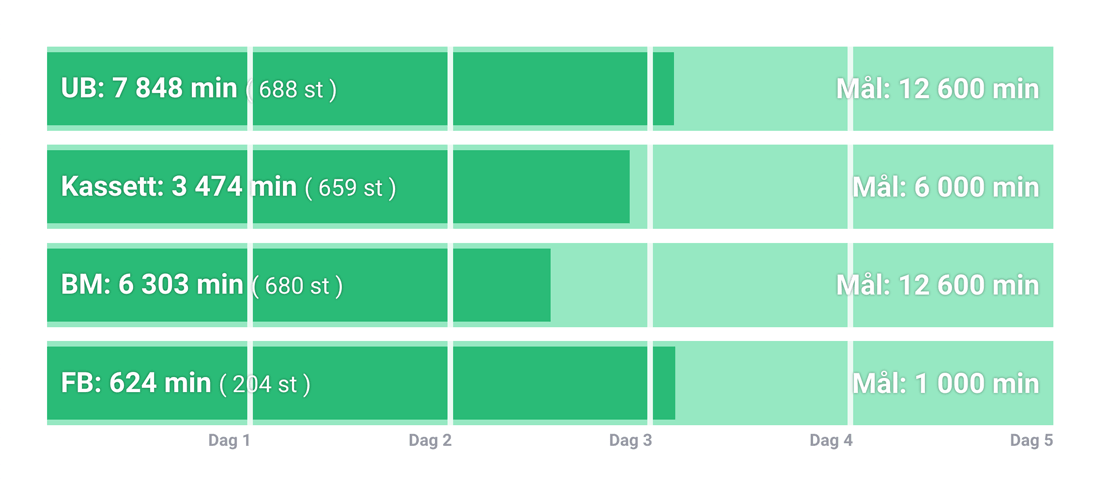

The production rate in relation to set weekly goals is updated in real time on large screens above the factory floor. In the warehouse, Boards on Fire visualizes the number of cubic meters picked for each employee, which has led to a big step forward in efficiency. Better control of the current situation has also made it possible to redistribute available staff in a smart way to where they are needed most at the moment.

– Since the start, we have had a very good collaboration with Boards on Fire when it comes to adapting their solutions to our needs. By integrating more with other systems we use, we can gather the information in Boards on Fire and have it easily accessible there. Then we want to continue working on implementing it at the factories in Lithuania to a greater extent, says Miika Porkola.

It’s now been six years since Scapa began using Boards on Fire in their operations and a lot has happened since then. In May 2025, we visited Scapa’s factory in Alvesta and had the chance to speak with Production Manager Andreas Knobloch about how the work has evolved, the results they’ve seen, and their outlook for the future.

– We still use Boards on Fire daily in our pulse meetings, on the shop floor, and across other parts of the production chain. Engagement remains high, and the interest in submitting improvement suggestions has grown, which helps us develop and streamline production. Every workstation is equipped with at least one Boards on Fire board, making it easier – and more motivating – to follow up on production, says Andreas.

He goes on to explain that the best ideas often come from the floor, and that the digital solution from Boards on Fire has been so well received that it’s now also implemented in their factories in Lithuania, where it’s used to monitor delivered production. The Alvesta plant holds daily meetings with the Lithuanian sites, and thanks to Boards on Fire, they can quickly share important information between locations.

Furthermore, Andreas explains that efficiency has increased by 60% thanks to Boards on Fire’s ability to visualize key KPIs, deviations, and improvements.

Finally, Andreas emphasizes that Boards on Fire is a key factor in delivering the right product, at the right time, and with the right quality. Especially because of its ability to make performance and priorities clearly visible.

Free web demo