Digital dashboards that help you identify deviations and make the right decisions.

Capture your deviations and turn them into improvements

Continuous improvement, Kaizen boards, PDCA and other tools.

All your team’s tasks, neatly organized in one weekly view.

Improve key performance indicators within your specific focus areas with our SQCDP board.

Use the PDCA cycle as a tool to improve both quality and processes

Digital tools for 5S work, recurring audits, and a well-organized workplace.

Visualize KPIs and communicate effectively throughout the entire organization.

Basic project management and activity boards.

Kanban is a powerful method for visualizing, managing, and optimizing workflows.

Digital dashboards for takt time flow with takt time counter and stop time log.

Digital visitor registration provides full control over all planned and executed visits to your business.

In a manufacturing operation, a lack of visibility into production can quickly lead to delays, downtime, and costly mistakes. By having a clear, real-time view, it becomes possible to act proactively, make data-driven decisions, and continuously improve operations. In this article, we explore various tools for gaining visibility in manufacturing.

To run an efficient manufacturing operation, you need a clear overview of production in real time. Without this visibility, it’s like looking for a needle in a haystack, making it difficult to identify and resolve issues, especially in a day-to-day environment affected by staff shortages and fluctuating demand. Reliable information about processes, status, production pace, and quality is therefore essential for continuous improvement.

With clear visibility into operations, you can act proactively and make data-driven decisions, rather than reacting only after problems have already impacted results. In this text, we explore why visibility in manufacturing is critical and the different forms it can take.

Visibility in manufacturing means having a clear and up-to-date picture of production in real time. It involves connecting people, machines, and systems to see exactly what is happening on the shop floor and across the entire value chain.

With the right visibility, you can quickly answer three key questions:

The goal is not just to collect data from different sources, but to make it visible and actionable, enabling fast and well-informed decision-making.

By leveraging different forms of visibility in production, organizations can gain a clearer understanding of their processes and make well-informed decisions.

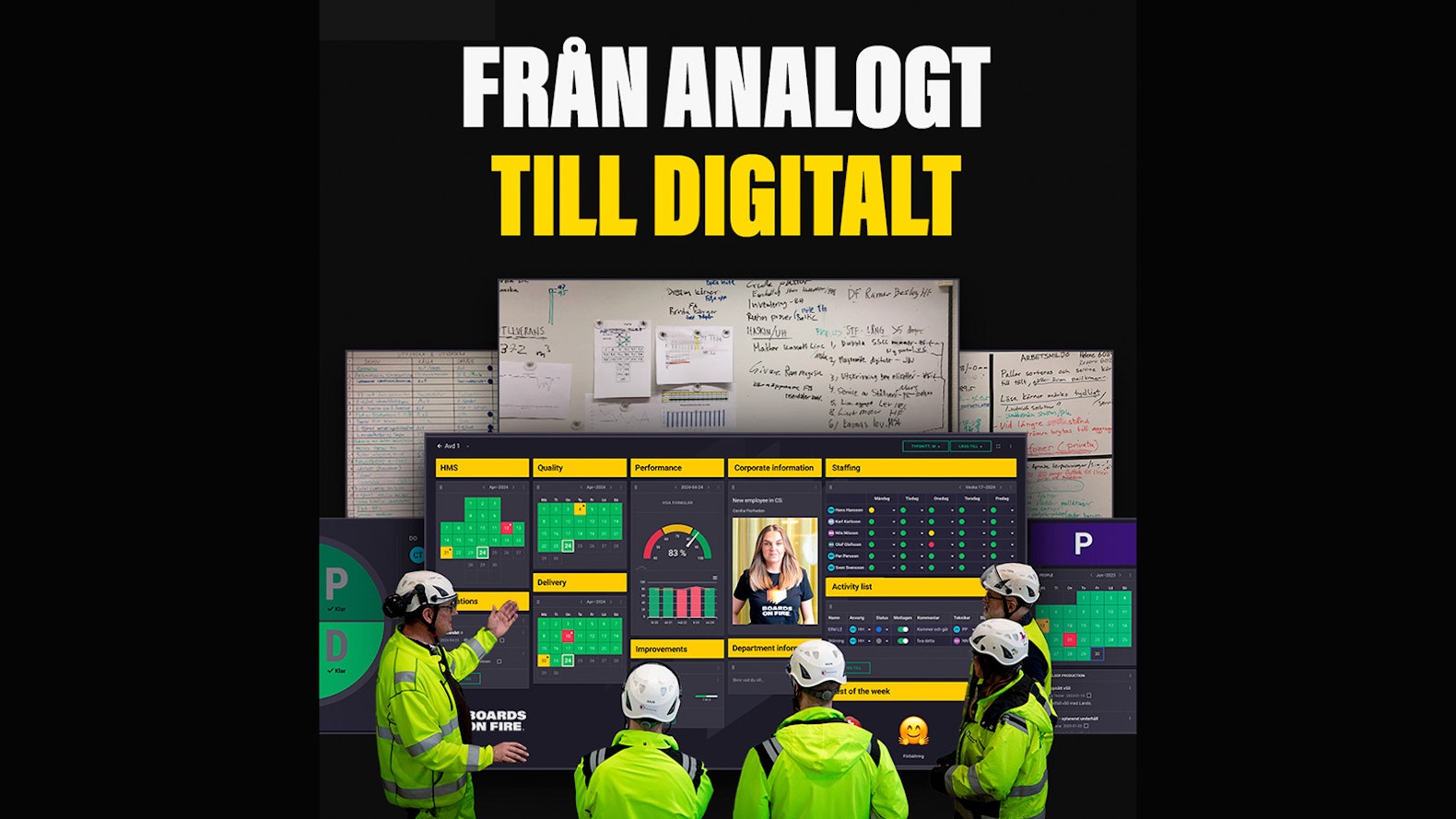

Boards on Fire is a digital tool for daily management that consolidates all data in one place. With Boards on Fire, you can easily visualize key metrics, deviations, improvements, and production goals.

With real-time data from Boards on Fire, teams no longer have to wait for reports and decision documents, which can often be delayed due to administrative tasks. All information is immediately available, allowing teams to act quickly on issues and improve production efficiency.

Boards on Fire makes it easy to see why downtime occurs and to manage deviations directly on the production floor. Teams can quickly address problems, follow up on actions, and reduce the risk of further stoppages. This frees up time and resources that can instead be used for continuous improvements and enhancing overall production efficiency.

By visualizing quality issues early, teams can prevent defects from spreading through production. Boards on Fire makes it easier to follow standards, reduce scrap and rework, and ensure that products consistently meet high-quality standards.

When operators and supervisors can see how their work impacts results, they become more engaged and take greater ownership. Feedback and improvements are visible directly in Boards on Fire, making learning and development more effective.

Boards on Fire provides a complete overview of production, making it easier to implement quick adjustments when deviations or disruptions occur. Production can be scaled up or down efficiently, and resources are used optimally. For example, if a deviation cannot be handled at the team level, it can be escalated to the next level for immediate action.

When all functions within the organization work from the same data, communication becomes clearer. Boards on Fire creates a shared view of the situation, making it easier to set common goals, coordinate actions, and at the same time inspire a healthy sense of competition between teams.

Boards on Fire is a digital tool for daily management that consolidates all data in one place. With Boards on Fire, you can easily visualize key metrics, deviations, improvements, and production goals.

Concrete results: AP&T Group, a manufacturing company specializing in efficient sheet metal and fiber forming solutions, struggled to establish a clear routine for managing deviations. With Boards on Fire’s digital daily management solution, a shared structure was implemented, leading to faster corrective actions and over 450 improvements completed. Read more here.

For a manufacturing operation to be efficient and competitive, visibility into production is essential. By having a clear, up-to-date, real-time view of processes, machines, personnel, quality, materials, and the supply chain, organizations can act proactively, make informed decisions, and quickly address issues before they impact results. Digital tools like Boards on Fire collect and visualize this information in a simple and accessible way, enabling increased productivity, higher quality, more engaged employees, better collaboration, and greater flexibility in production. In short, having visibility across the entire value chain is the key to continuous improvement and long-term success.

Want to see how increased visibility could look in your production? Digital daily management is an effective first step.

Happens at Boards on Fire

Free web demo