Digital dashboards that help you identify deviations and make the right decisions.

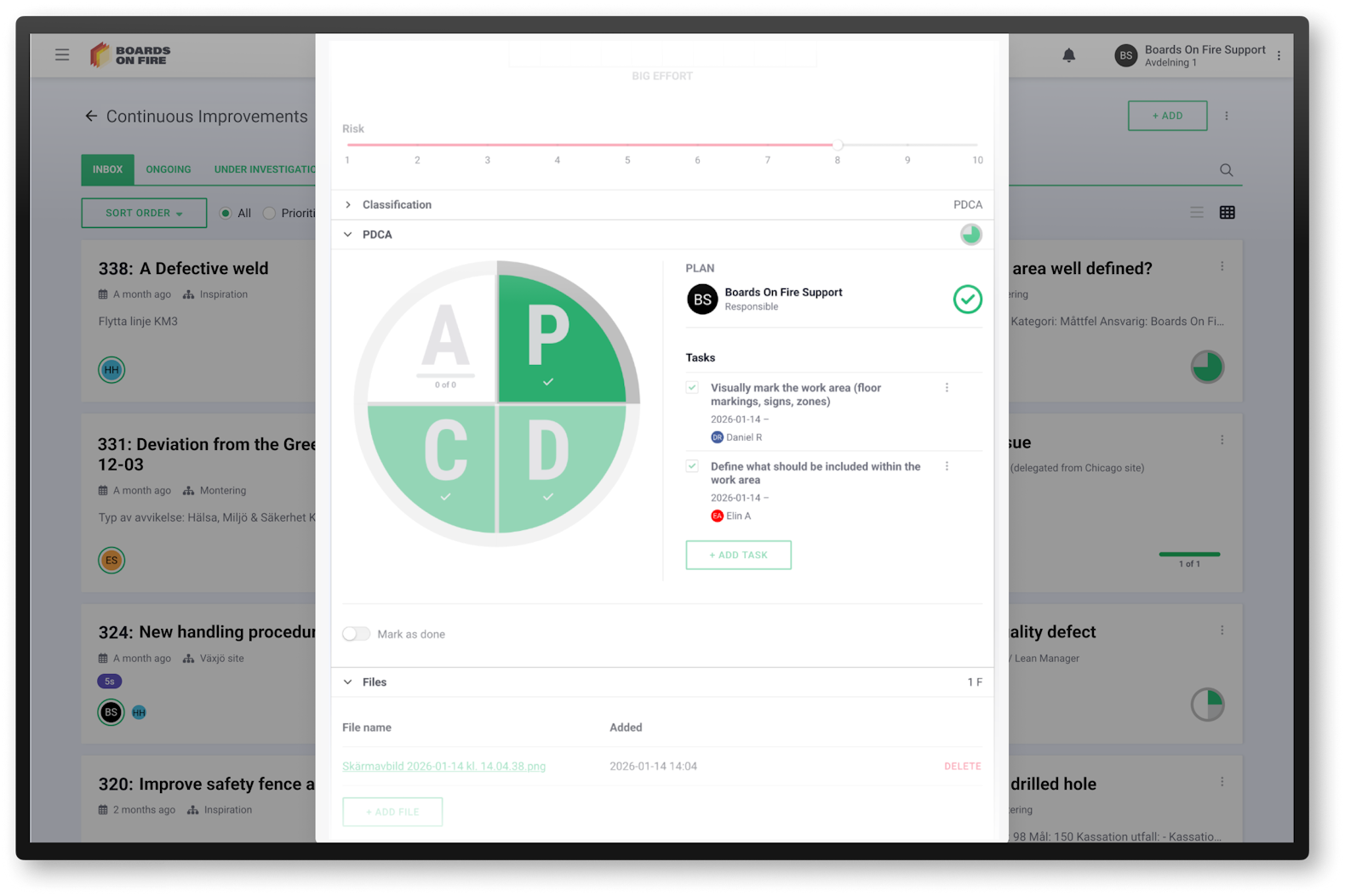

Capture your deviations and turn them into improvements

Continuous improvement, Kaizen boards, PDCA and other tools.

All your team’s tasks, neatly organized in one weekly view.

Improve key performance indicators within your specific focus areas with our SQCDP board.

Use the PDCA cycle as a tool to improve both quality and processes

Digital tools for 5S work, recurring audits, and a well-organized workplace.

Visualize KPIs and communicate effectively throughout the entire organization.

Basic project management and activity boards.

Kanban is a powerful method for visualizing, managing, and optimizing workflows.

Digital dashboards for takt time flow with takt time counter and stop time log.

Digital visitor registration provides full control over all planned and executed visits to your business.

In manufacturing, where demands rise and conditions constantly change, new technology and automation alone are not enough. Long-term competitiveness requires a culture of daily improvements, driven close to the operations and with engagement from the entire organization. This is where Kaizen makes a difference.

Leading a manufacturing operation can be compared to steering a ship on the open sea, where conditions are constantly changing. Costs rise, margins shrink, quality requirements increase, supply chains become more complex, and safety standards grow stricter. Trying to meet these challenges solely through investments in new technology, automation, or digital systems is like putting a more powerful engine on the ship without improving the crew’s way of working. Long-term success requires a culture where continuous improvement is a natural part of daily operations – in other words, a Kaizen culture.

A Kaizen culture is based on a mindset where improvement work permeates the entire organization. All employees are expected to contribute to developing work methods, processes, and results in their daily work, making improvements as natural as production, management, quality, and safety.

In practice, Kaizen is characterized by:

Kaizen differs from traditional improvement initiatives because engagement comes from within the organization itself. All employees, regardless of role, are given responsibility and authority to identify risks, inefficiencies, and waste. When improvements happen continuously, even small adjustments can lead to significant long-term effects.

However, many organizations get stuck here. Ideas remain on whiteboards or in notes without follow-up. Without a shared approach, improvements risk staying at the level of intention. By working systematically with small, recurring improvements, organizations can create stable development that strengthens safety, efficiency, and competitiveness.

Kaizen is not about achieving results overnight; it is about making continuous improvements every day and truly integrating improvement work into daily operations. With the right tools and mindset, every employee can contribute to learning, adaptation, and continuous improvements across the shop floor.

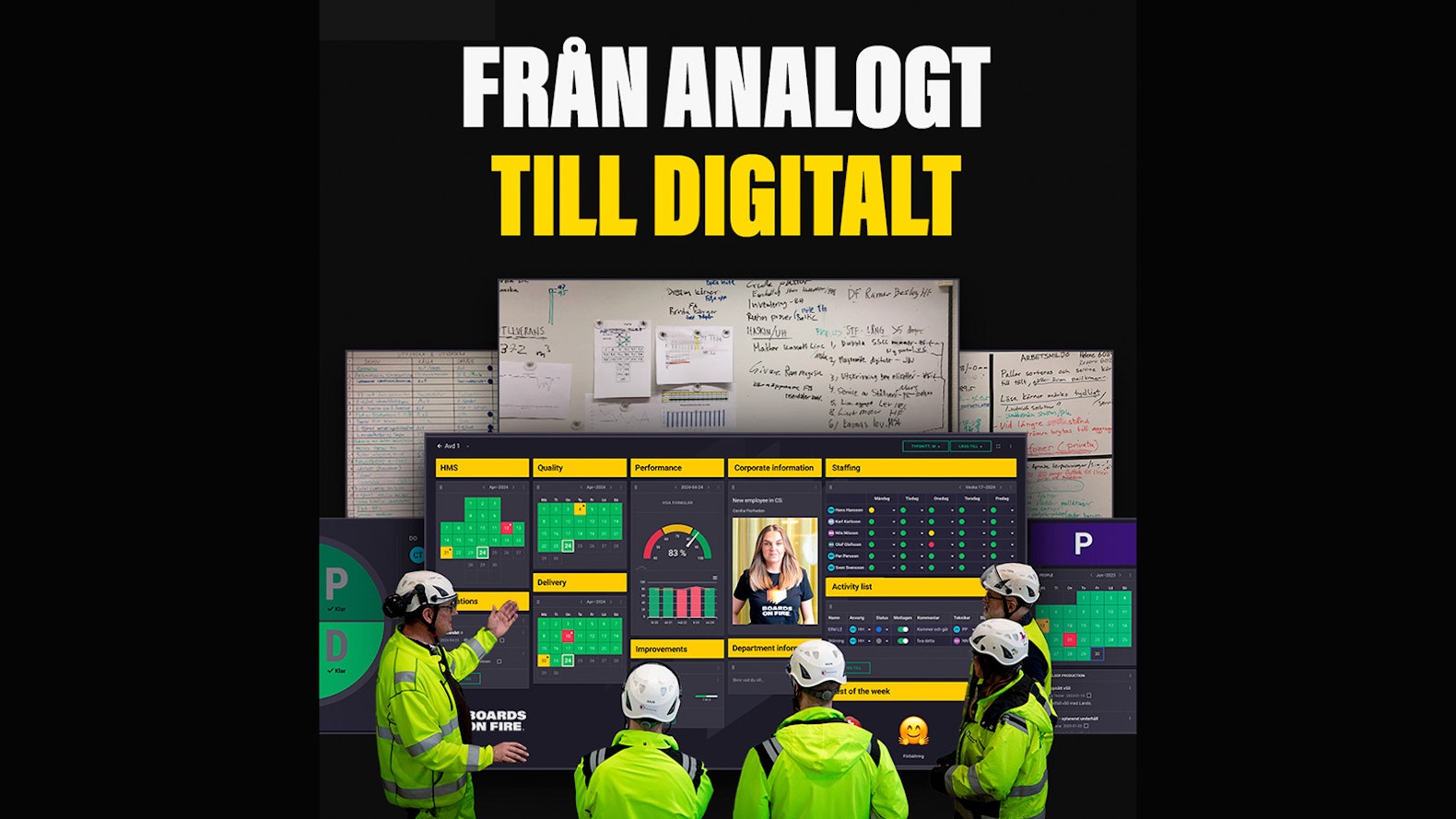

With Boards on Fire, Kaizen culture becomes tangible and easy to implement in practice:

The result: improved safety and quality, more engaged employees, more reliable equipment, and greater organizational resilience. Boards on Fire makes continuous improvement a natural part of everyday operations.

Driving cultural change through Kaizen is a long-term journey that requires persistence and consistency. Here are some fundamental steps to get started and keep improvement work alive:

When a Kaizen culture is in place, its effects are visible in daily operations:

Several tools facilitate improvement work, problem-solving, and rapid decision-making. Notably, Boards on Fire provides digital solutions that make it easy to scale and visualize Kaizen culture:

Boards on Fire Digital Tools for Daily Management

Tools to Reduce Waste

Problem-Solving Tools

A Kaizen culture is ultimately about building long-term strength in a constantly changing environment. When continuous improvements become a natural part of daily work, safety, quality, and engagement increase, while the organization becomes more resilient and competitive. With the right approach, clear leadership, and supportive tools, Kaizen can turn from ambition into reality—every day, across the entire organization.

Happens at Boards on Fire

Free web demo