Digital dashboards that help you identify deviations and make the right decisions.

Capture your deviations and turn them into improvements

Continuous improvement, Kaizen boards, PDCA and other tools.

All your team’s tasks, neatly organized in one weekly view.

Improve key performance indicators within your specific focus areas with our SQCDP board.

Use the PDCA cycle as a tool to improve both quality and processes

Digital tools for 5S work, recurring audits, and a well-organized workplace.

Visualize KPIs and communicate effectively throughout the entire organization.

Basic project management and activity boards.

Kanban is a powerful method for visualizing, managing, and optimizing workflows.

Digital dashboards for takt time flow with takt time counter and stop time log.

Digital visitor registration provides full control over all planned and executed visits to your business.

A Gemba Walk is a powerful Lean method used to identify waste and improvement opportunities, directly where value is created. By visiting the workplace and observing processes firsthand, management gains insights that go beyond reports and assumptions.

A Gemba Walk is one of the most powerful tools for understanding the current state of a business, identifying waste, and creating opportunities for learning and improvement. This method, which is a central part of Lean, involves management and employees visiting the place where value is created (gemba = “the real place” in Japanese), such as the production floor. The goal is to observe, understand, and learn from daily work rather than to control, judge, or point out flaws.

At its core, a Gemba Walk is about moving from assumptions and reports to firsthand observations. By following the workflow in practice, it becomes possible to identify where unnecessary delays, detours, or rework occur insights that form the foundation for real improvement work.

A key principle of Gemba Walks is to leverage the knowledge of those doing the work. These employees have the deepest understanding of the organization’s challenges and potential. When management’s observations are combined with employees’ experiences, a reality-based foundation for improvements is created, far beyond gut feeling or assumptions.

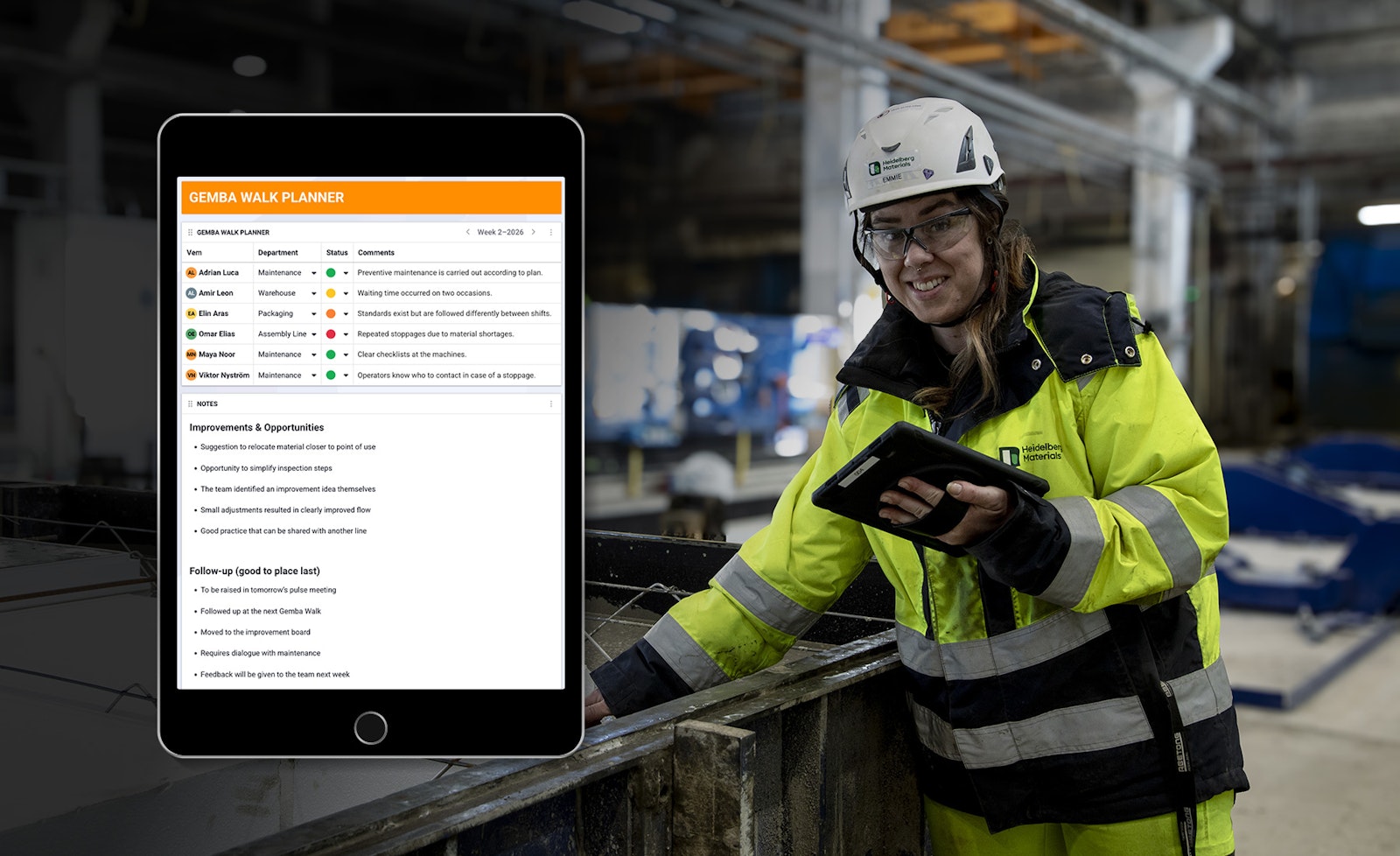

Digital Tools for Gemba Walks

Gemba Walks can be conducted in various ways. The most common approach is using lists, often on whiteboards or paper. Regardless of format, the purpose is the same: to understand how work is actually performed and to drive improvements.

With Boards on Fire’s digital solution for daily management, the value of Gemba Walks is enhanced even further. You can easily plan, conduct, and follow up on rounds directly via mobile, tablet, or computer, without losing your presence on the floor.

By combining physical Gemba Walks with digital daily management, observations are not just noted in the moment, they are preserved over time, compared, and translated into concrete actions. All relevant information is collected on a single platform, from production data and KPIs to improvement proposals and 5S evaluations. This makes Gemba Walks more than a routine review; they become a structured, data-driven, and powerful tool for continuous improvement and long-term operational development.

A Gemba Walk is simple to perform but requires discipline and attention to detail. Here’s how to do it:

A Gemba Walk is not a meeting, an inspection, or just another method. It is a mindset: leading by understanding reality together with those who live it every day. It focuses on understanding what works well today, what makes work difficult or unnecessarily complicated, and where delays, interruptions, or rework occur.

Three things to keep in mind during Gemba Walks:

Three things to avoid:

Book a demo, and we’ll be happy to show how Boards on Fire can support your organization!

Happens at Boards on Fire

Free web demo