Assa Abloy, today a global leader in locks and security solutions with over 50,000 employees in more than 70 countries, is driving an extensive digitalization initiative in its Swedish factories. Both Eskilstuna and the sister site in Mölnlycke have embarked on a journey toward a more efficient, data-driven daily operation, with both factories highlighting Boards on Fire as a central part of this transformation.

– Thanks to Boards on Fire, the management team can save up to four hours per week by having all information consolidated in a single system. We no longer have to enter the same data in multiple systems and can instead focus on what truly matters,” says Sascha Sager, Operational Excellence Lead at Assa Abloy in Mölnlycke.

A significant step toward digital daily management

For many years, both Eskilstuna and Mölnlycke relied on traditional whiteboards, handwritten notes, and separate Excel files. This manual approach made it difficult to get a clear overview and to quickly distribute information consistently. The change began in Eskilstuna, where an employee introduced Boards on Fire based on experiences from a previous workplace, marking the starting point for the factory’s digitalization of daily management.

The goal was to gather data and reports from various systems on a single platform, create a clearer overview of KPIs, and make daily management more accessible to all employees, ultimately increasing production efficiency. Since then, the Eskilstuna site has been using Boards on Fire for over three years.

Automation and visualization for smoother production

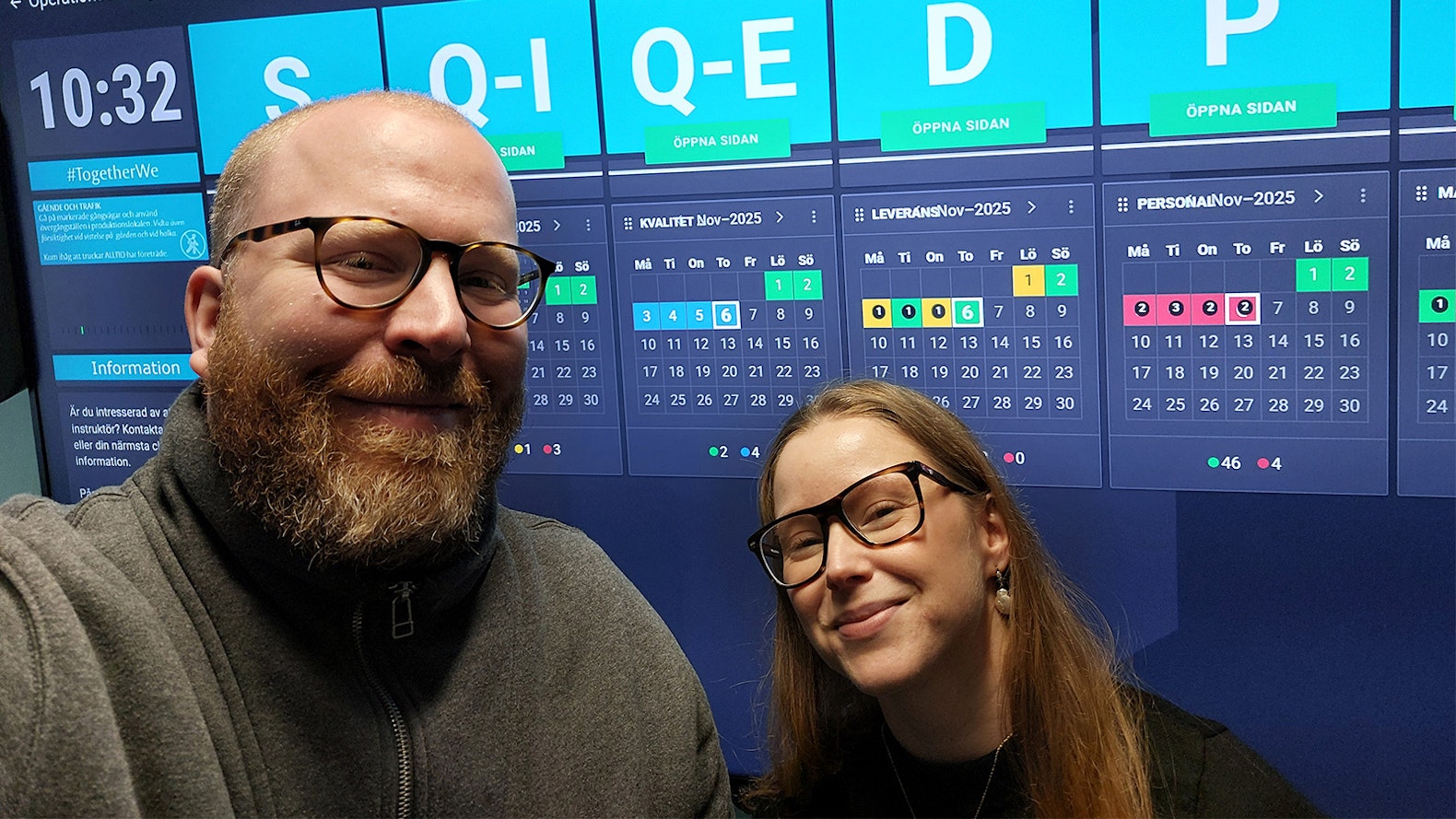

Since the implementation of Boards on Fire, work routines at the Eskilstuna factory have changed significantly. Both management and employees can now gain a clear and consolidated overview of the operations.

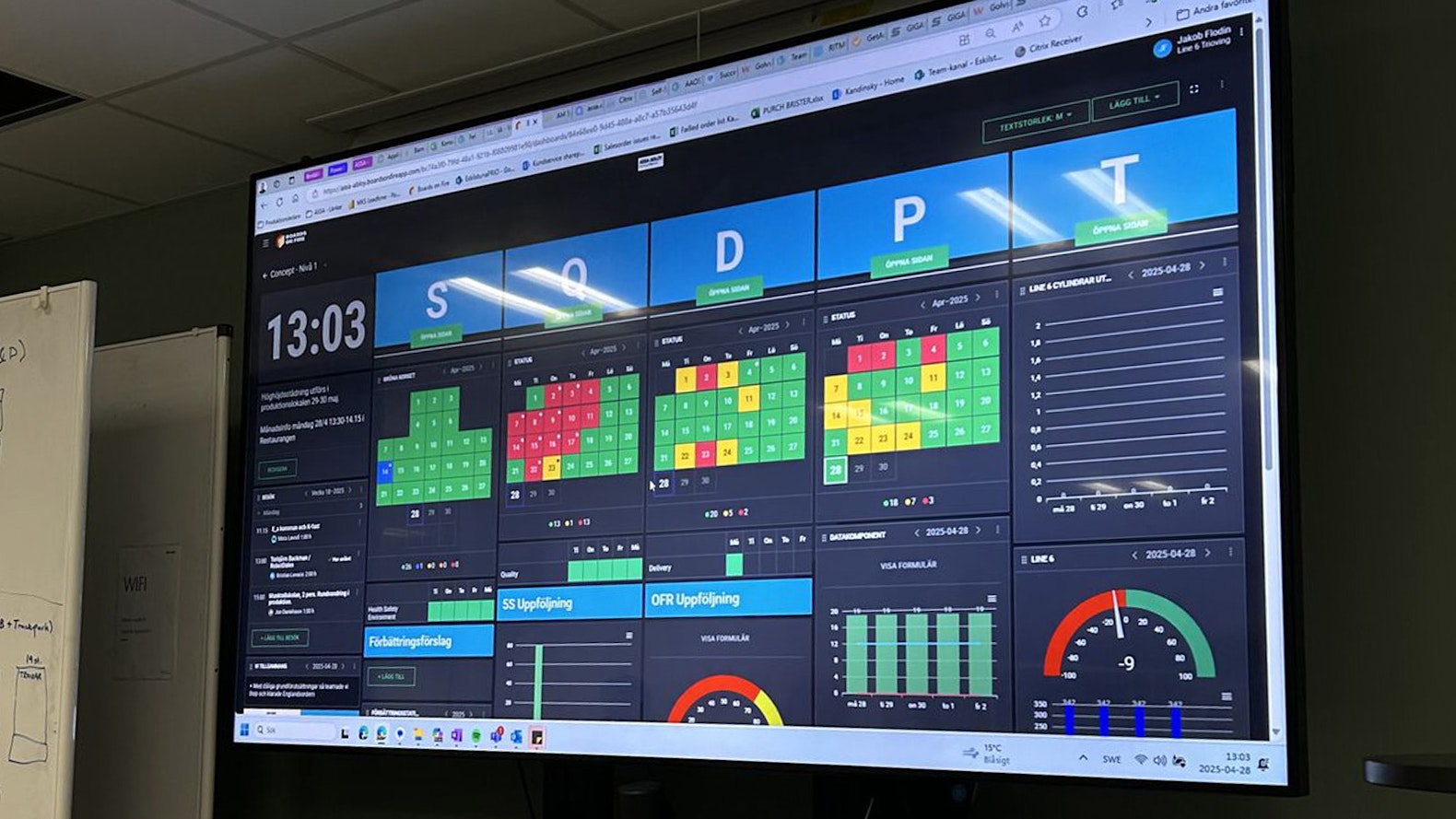

– Boards on Fire’s digital pulse boards make it both visually appealing and easy for us to track our KPIs and SQDP points collectively, says Jakob Flodin, Production Supervisor at Assa Abloy.

Jakob further explains that the system has also provided better insight into workforce allocation, enabling optimized resource usage and increased efficiency. Communication flows across the organization have improved, and all employees can quickly access relevant information through Boards on Fire’s aggregation capabilities, regardless of organizational level. Automation of the cylinder machines, which are part of the production process, has also contributed to a fast and clear overview of production, enabling a continuous weekly production rhythm and facilitating process planning.

Mölnlycke steps toward a unified digital platform

Inspired by the results at the Eskilstuna factory, the sister site in Mölnlycke also decided to leave behind manual processes and implement the same digital solution for daily management.

– We heard about Boards on Fire through our sister site in Eskilstuna, which had already implemented it. What caught our interest was the possibility to replace multiple systems and manual tools with a single digital platform where we could consolidate everything from deviations to improvements and KPIs, with information automatically mirrored across departments, says Sascha Sager, Operational Excellence Lead at Assa Abloy in Mölnlycke.

Since the implementation, communication between shifts has become more efficient, and collaboration between departments has improved because everyone now works within the same system and structure. Another key improvement is the centralization of all information related to improvement activities. Instead of collecting 5S lists, waste walks, and ideas in separate folders and Excel files, everything is now managed in the improvement module of Boards on Fire. Each activity follows the PDCA principle and is traceable from start to finish, providing both better follow-up and higher quality in improvement work.

Smooth integration and positive reception at both factories

Boards on Fire quickly became a natural part of daily operations, and the transition to the new system was much smoother than expected. For those considering implementation, this demonstrates that the process does not need to be time-consuming or complicated.

– Integration with Power BI and Excel has been very straightforward, and the system makes daily management much more transparent, say Jakob and Tony.

Another strength is the API integration, which allows data from existing systems to be consolidated in one place. This gives the team full control over information, enables decisions based on clear real-time insights, and allows them to work more efficiently and confidently.

The system has been very positively received. Employees feel more informed and involved in what is happening in the operations, while management notes that the boards clearly help foster engagement and understanding of both results and improvement initiatives.

Saving approximately four hours per week

At the Eskilstuna site, the deviation module is currently under development and is expected to save between one and five hours per week by eliminating duplicate data entry.

– Once fully implemented, the module will allow deviations to be managed in a more structured, visual, and efficient way, which is estimated to save one to five hours per week, mainly by reducing the time required to use multiple systems. It will also enable more effective communication between production and quality teams, explain Jakob and Tony.

In Mölnlycke, the ten team leaders now save 3 hours per week each thanks to the automatic aggregation of information in Boards on Fire. Previously, both boards and Excel files had to be updated manually, which was not only time-consuming but also made it difficult to keep departments synchronized. Data is now automatically consolidated on a single platform, ensuring information is always up to date and accessible to both shift leaders and employees. The result is faster decision-making, better follow-up of improvement activities, and a more unified way of working across the factory.

Both factories continue to develop their digital management through additional API integrations, increased automation, and the establishment of central OpEx boards, where site-wide KPIs are monitored in real time.

Two factories, one shared success

Even though Eskilstuna and Mölnlycke started their digitalization efforts at different times, both factories report the same results: Boards on Fire has become an integral part of the culture for daily management and continuous improvement, and the development journey continues.

Boards on Fire is seen as a long-term tool in improvement work, with usage continuously evolving. Currently, efforts are underway to introduce more automation through data carriers and API connections to further minimize manual work. A central OpEx board, a so-called war room, has also been established. Here, site-wide KPIs, project status, and improvement activities are monitored in real time, strengthening both leadership and follow-up at all levels.