Digital dashboards that help you identify deviations and make the right decisions.

Capture your deviations and turn them into improvements

Continuous improvement, Kaizen boards, PDCA and other tools.

All your team’s tasks, neatly organized in one weekly view.

Improve key performance indicators within your specific focus areas with our SQCDP board.

Use the PDCA cycle as a tool to improve both quality and processes

Digital tools for 5S work, recurring audits, and a well-organized workplace.

Visualize KPIs and communicate effectively throughout the entire organization.

Basic project management and activity boards.

Kanban is a powerful method for visualizing, managing, and optimizing workflows.

Digital dashboards for takt time flow with takt time counter and stop time log.

Digital visitor registration provides full control over all planned and executed visits to your business.

Structure, transparency, and continuous improvement are the foundation of every successful Lean organization. Everything is interconnected, and when daily management truly works, clear focus, increased accountability, and a shared drive forward emerge throughout the entire organization.

In the role of a Lean Manager, daily life is closely tied to daily management. It’s about clarifying goals, visualizing performance against KPIs, capturing deviations in time, and translating them into concrete improvement actions. This often takes the form of new ways of working, updated standards, and adjusted processes. All of this aims to create stability in the workflow and drive the organization forward, step by step.

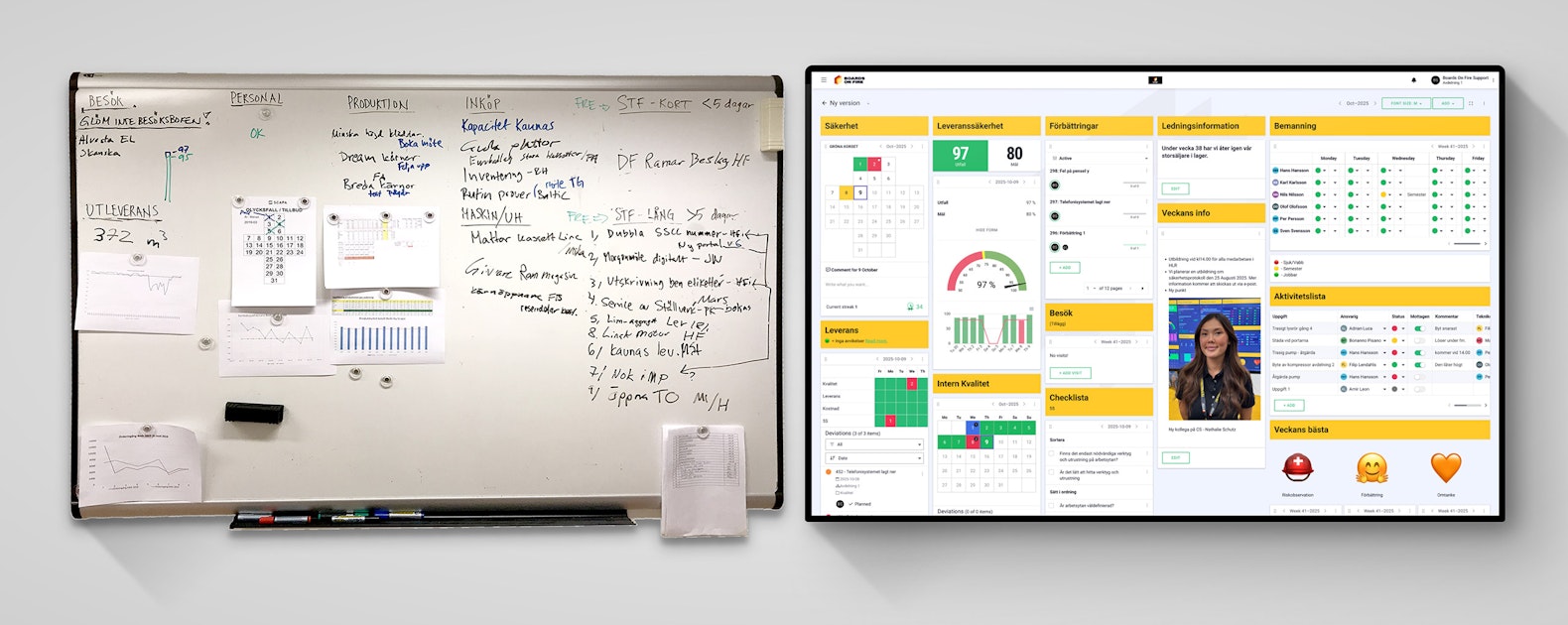

But reality often brings challenges. Traditional whiteboards quickly fill up with handwritten numbers, sticky notes, and annotations that are hard to read and even harder to track over time. Much of meeting time is spent collecting, updating, and explaining numbers instead of analyzing root causes and deciding on actions. The information becomes static, outdated, and dependent on specific individuals.

Common challenges in this approach include:

As a result, daily management risks becoming more administrative than value-creating. Instead of focusing on learning and improvement, the organization gets stuck in manual handling and lacks overall visibility.

To make daily management simpler, more transparent, and data-driven, digital tools such as Boards on Fire now help organizations track goals, visualize KPIs, and drive improvements in real time. Here are some concrete examples of how Boards on Fire facilitates the work:

Our customers’ Lean Managers report that Boards on Fire makes a real difference in daily management, from planning to continuous improvements.

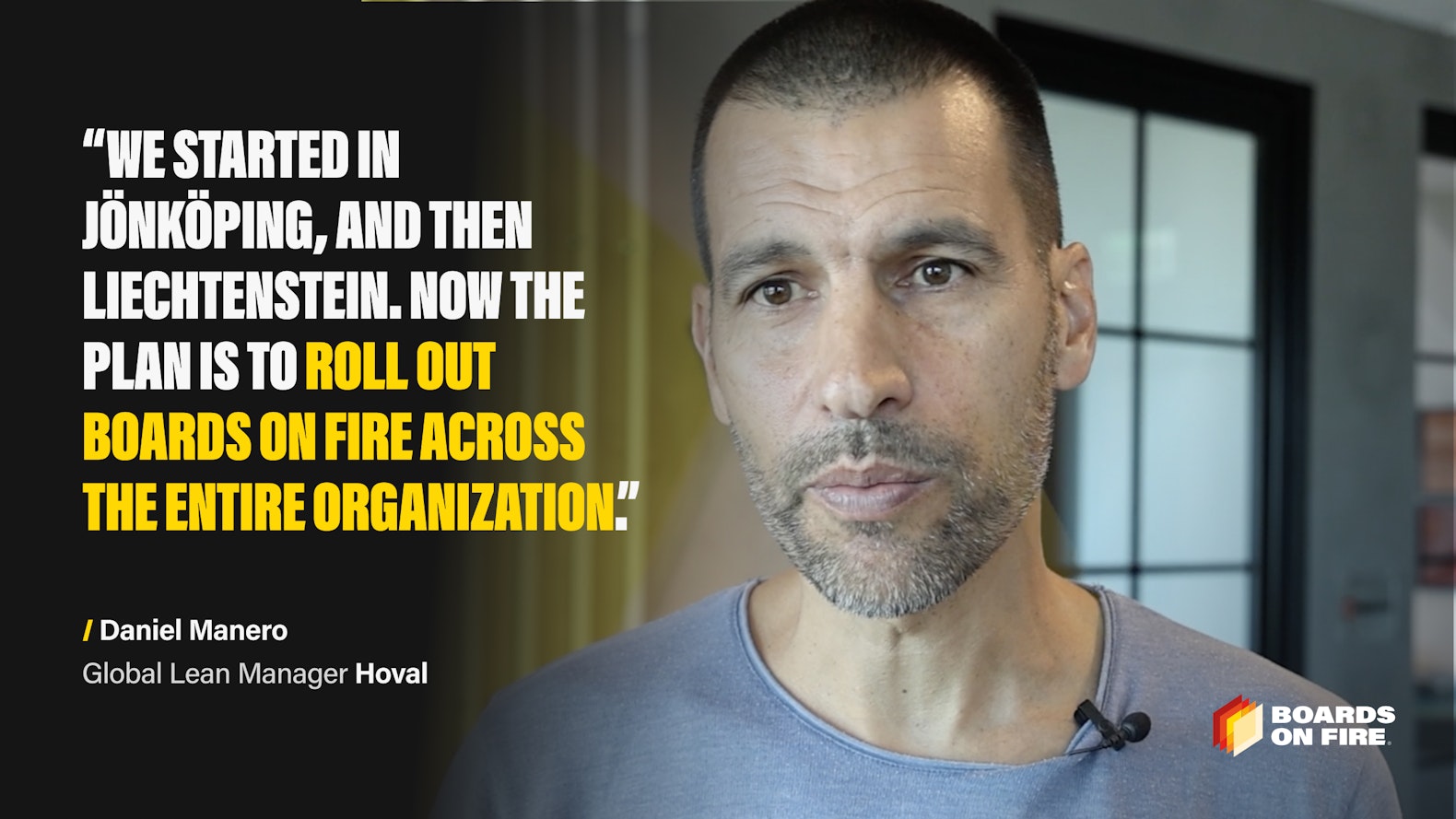

The Hoval Group is a global leader in heating and indoor climate solutions. After implementing Boards on Fire at its Jönköping factory and seeing clear positive effects, the factory in Liechtenstein also took an important step toward digitalization. Soon, Hoval will roll out Boards on Fire across the entire organization to simplify collaboration between factories in Europe. All departments can follow the same processes and access real-time data, strengthening coordination and decision-making across borders.

One reason Hoval chose Boards on Fire is the tool’s flexibility and ability to consolidate all processes in one place. This streamlines communication both domestically and internationally, while data visualization increases transparency and strengthens employee engagement through KPI discussions and comparisons.

Boards on Fire has become an integral part of the Lean work at Swecon, a Volvo dealer. Daily management, project planning, 5S, deviations, and improvement initiatives are all handled directly in the system, exactly where the information is needed. The result is a more structured, efficient, and transparent way of working for both Lean Managers and employees.

"Boards on Fire makes it much clearer for us to follow up on our work each week. The notes function, which we call ‘Other Information,’ has gone from being static to becoming a tool for continuous follow-up. It makes it easy to identify areas for improvement and share best practices across the organization."

– Peter Norgren, Lean Manager at Swecon.

Learn more about how Swecon transitioned from analog to digital daily management across the organization.

From a Lean perspective, Boards on Fire is more than just a digital tool—it is a support system that reinforces the principles of visual management, standardization, and continuous improvement. It frees up time from administrative tasks, provides better decision-making data, and strengthens daily management, which in turn leads to greater control, higher engagement, and a faster pace of improvement—without compromising the core of Lean.

Happens at Boards on Fire

Free web demo