Digital dashboards that help you identify deviations and make the right decisions.

Capture your deviations and turn them into improvements

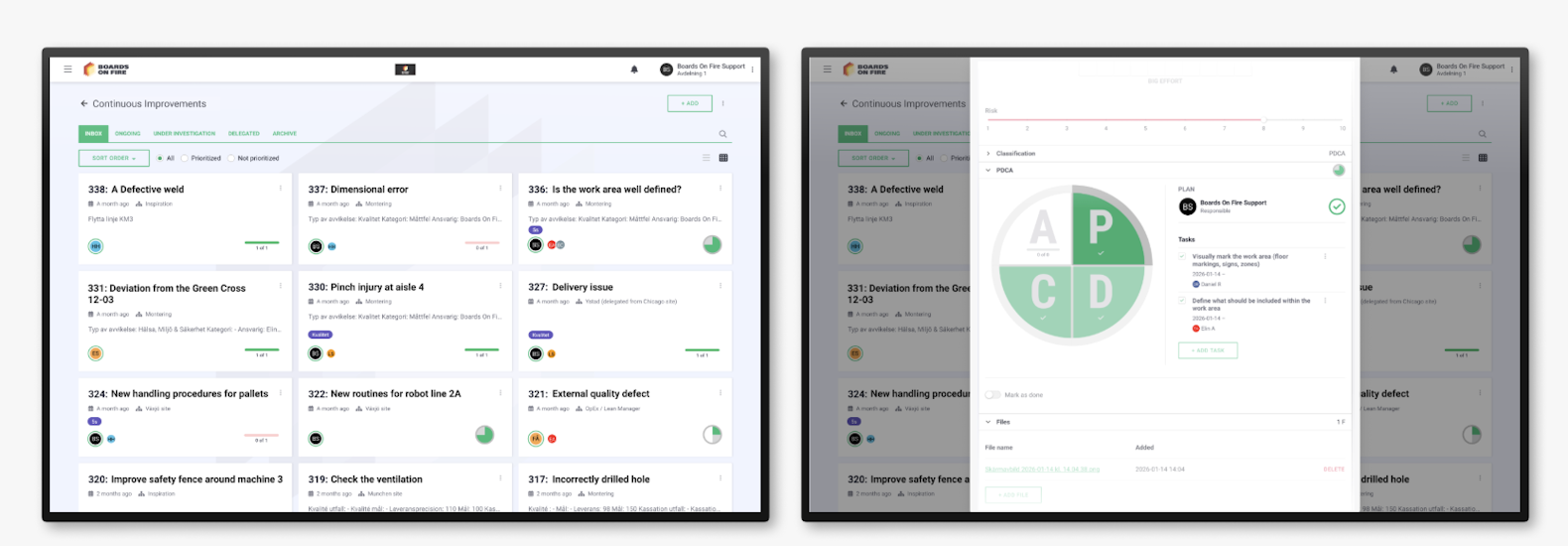

Continuous improvement, Kaizen boards, PDCA and other tools.

All your team’s tasks, neatly organized in one weekly view.

Improve key performance indicators within your specific focus areas with our SQCDP board.

Use the PDCA cycle as a tool to improve both quality and processes

Digital tools for 5S work, recurring audits, and a well-organized workplace.

Visualize KPIs and communicate effectively throughout the entire organization.

Basic project management and activity boards.

Kanban is a powerful method for visualizing, managing, and optimizing workflows.

Digital dashboards for takt time flow with takt time counter and stop time log.

Digital visitor registration provides full control over all planned and executed visits to your business.

How much of your time as a production manager is spent collecting and compiling key metrics, updating whiteboards with the latest figures, and ensuring that the information is fully accurate before it can be shared across the organization?

As a production manager, you navigate daily at the intersection of people, processes, and goals, where quick decisions and continuous follow-up are part of everyday life. To act effectively, you need a clear picture of the current situation, but when information is spread across whiteboards, notes, and various systems, it becomes difficult to get an accurate overview. Analog methods like these risk creating information gaps, duplicated work, and uncertainty about which data is actually up to date, factors that can impact production efficiency and results.

In this article, we highlight some of the most common challenges faced by production managers and how they can be addressed using digital tools to make daily operations more efficient.

Challenges are an inherent part of daily life in production, as in many other professions. In the industrial sector, they are often interconnected and can trigger chain reactions that affect pace, quality, and results. At the same time, it is by managing these challenges that we can grow and continuously improve work processes. Below are some of the most prominent challenges:

In recent years, digital tools have evolved from being mere support systems to becoming a crucial key for production managers who want better control over daily operations. Instead of relying on whiteboards, paper, and manual compilations, all information and processes can now be visualized digitally, ensuring that both managers and teams always have the same up-to-date view of production.

Boards on Fire’s digital solution for daily management consolidates all essential information into easy-to-read digital boards that can be displayed on screens throughout the factory. By visualizing production status in real time, teams gain immediate visibility into deviations, bottlenecks, ongoing activities, and KPIs. This enables proactive action rather than last-minute reactions, reducing the risk of delays and quality issues.

The solution also provides better conditions for continuous improvement. By centralizing historical data, deviations, and actions in one place, it becomes easier to analyze patterns, track results, and implement lessons learned that strengthen the production flow over time. Key metrics are updated automatically in real time, making reporting fast, accurate, and transparent, and providing both management and teams with a reliable basis for decision-making.

In addition to the above, the platform can be connected to other systems via file or API integration. As long as data can be exported to a CSV file and sent through file integration, or transferred to us via API, it can be visualized in Boards on Fire. This means that information from, for example, ERP, CRM, MES, and PLM systems, production systems, management systems, or machinery can be consolidated and presented in Boards on Fire without requiring pre-built standard integrations with each individual system. In this way, the entire production operation gains a unified and up-to-date real-time overview.

But the value goes beyond structure and efficiency. When information is accessible, clear, and shared, engagement within the organization increases. Employees gain a better understanding of the bigger picture, clearer ownership of their tasks, and improved ability to influence outcomes. This fosters a sense of responsibility and more active participation in daily improvement work.

At the same time, modern, digital management signals that the company is at the forefront. It contributes to internal pride and strengthens the brand externally—towards customers, partners, and prospective employees. Working in a structured, data-driven way is perceived as professional, sustainable, and future-proof, offering a clear competitive advantage.

Key Benefits of Boards on Fire:

Today, Boards on Fire is used in over 135 countries, and its reach continues to grow. Here are some clear examples of return on investment (ROI) that our customers have achieved:

Boards on Fire offers flexible digital pulse boards that can easily be tailored to the needs of your organization, regardless of role or function. These boards consolidate production data, key metrics, and improvement initiatives in one place, updated in real time. This provides full visibility, simplifies follow-up, and creates better conditions for data-driven decisions and effective, continuous improvement. Additionally, all data can be aggregated across all organizational levels, enabling fast and well-informed decision-making.

Examples of What You Can Visualize on Your Boards:

No matter where your focus lies, the boards help you deliver the right information to the right person, exactly when it’s needed.

Production managers face daily challenges such as information gaps, duplicated work, uncertainty around KPIs, and time-consuming manual routines. Boards on Fire consolidates all information in one place and visualizes it on digital boards. These provide both management and employees with real-time visibility into KPIs, deviations, and ongoing activities, making it easy to act proactively.

With automated reporting, traceable deviation management, and smart integration capabilities, it becomes easier to make fast, data-driven decisions, engage the team, and foster a learning organization. The result? Less administration, increased transparency, and a production flow that shifts from reactive to strategically managed, exactly the support a production manager needs to handle everyday challenges.

Free web demo