Digital dashboards that help you identify deviations and make the right decisions.

Capture your deviations and turn them into improvements

Continuous improvement, Kaizen boards, PDCA and other tools.

All your team’s tasks, neatly organized in one weekly view.

Improve key performance indicators within your specific focus areas with our SQCDP board.

Use the PDCA cycle as a tool to improve both quality and processes

Digital tools for 5S work, recurring audits, and a well-organized workplace.

Visualize KPIs and communicate effectively throughout the entire organization.

Basic project management and activity boards.

Kanban is a powerful method for visualizing, managing, and optimizing workflows.

Digital dashboards for takt time flow with takt time counter and stop time log.

Digital visitor registration provides full control over all planned and executed visits to your business.

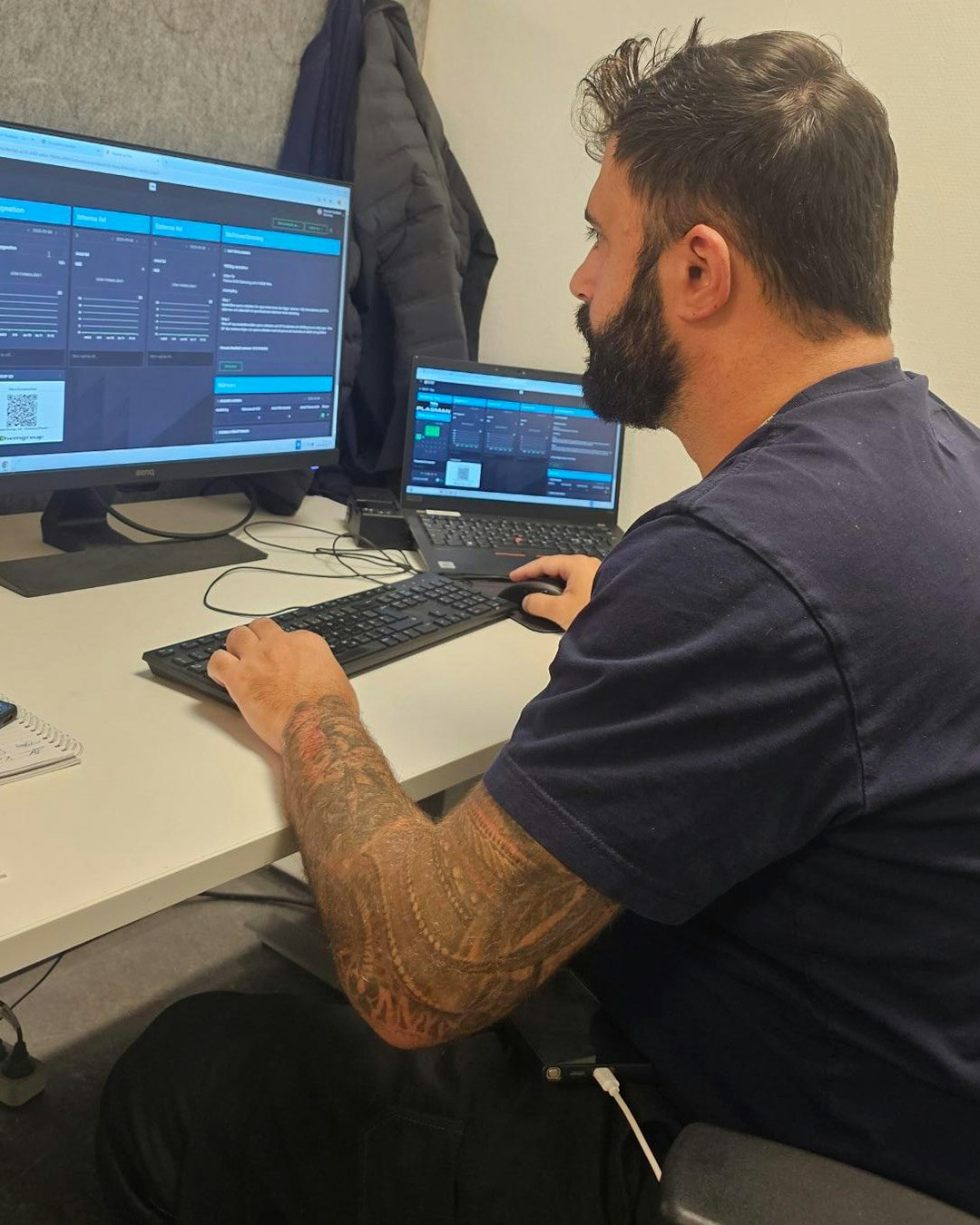

Just over three years ago, Plasman’s team in Gothenburg identified the need for a more efficient approach to daily management. That’s when they decided to start working with Boards on Fire, a decision that has already delivered impressive results, including significant time savings, increased productivity, and greater ownership among employees.

Plasman, formerly Plastal Group, has been supplying automotive components to OEMs, contract manufacturers, and distributors worldwide since 1978. The company offers complete solutions including toolmaking, injection molding, chroming, painting, surface finishing, and assembly. Today, Plasman has a global presence with operations in ten countries, maintaining a strong focus on quality and continuous development.

To make everyday work easier and gain a better overview of production, the Plasman team recognized the need for a modern, digital solution. When the production manager learned about Boards on Fire, it didn’t take long before the platform was implemented and ready to use in production.

Previously, Plasman relied on traditional whiteboards to update KPIs and key metrics each day. With around nine departments requiring their own boards, the process was time-consuming and it was difficult to keep information up to date. It was also common for someone to forget to fill in data or to use the wrong color, resulting in incorrect numbers and decreased productivity.

“Since the transition to Boards on Fire, we have primarily seen significant time savings. We no longer waste time running around updating boards manually, while at the same time achieving a higher and more consistent standard across the organization. Together with Boards on Fire, we have also further developed this through our 5S work,” says Hassan, Lean Manufacturing Excellence at Plasman in Gothenburg.

He also emphasizes that the shift from whiteboards to Boards on Fire was smooth and efficient, enabling Plasman to quickly adapt to the new way of working.

Since implementing Boards on Fire, Plasman has been able to consolidate all data in one place, streamlining daily operations. Hassan highlights the advantage of being able to use Boards on Fire across different devices such as computers, phones, or tablets.

“For example, we can easily check the assembly department’s action plan, whether we are physically present on the shop floor or not. It’s convenient to be able to follow production remotely via mobile,” Hassan explains.

Overall, Plasman has saved considerable time since adopting Boards on Fire. Previously, employees had to move between boards to keep information updated. Now, everything is just a couple of clicks away in the platform.

According to Hassan, this makes it easier to manage, delegate, and track KPIs and different tasks in real time. Meetings also take half the time they used to, while improvements can be monitored and managed effectively. Everything is archived within the system, eliminating the need to search through Excel files stored in private folders, which often get lost among other documents. With Boards on Fire, everything is collected and stored in the cloud.

For Plasman, several Boards on Fire features have proven especially valuable, particularly the action plan and the safety function with the green cross. Employees feel that the platform has made work both simpler and more engaging, as KPIs can be tracked in real time. It has also sparked a healthy sense of competition, both within and between departments, which in turn has led to increased productivity.

Both Hassan and Nicola also point out that the support from Boards on Fire has been highly appreciated, especially during the implementation phase.

“The support has been quick and effective. In one case, we received a response within 10–15 minutes, and a meeting was scheduled the very next day. I’m really satisfied,” says Nicola Tasevski, Production Supervisor at Plasman in Gothenburg.

Going forward, the Plasman team sees great potential in further developing their use of Boards on Fire by integrating it with their own ERP system to automatically collect and visualize data. Both Nicola and Hassan agree that Boards on Fire offers far more functionality than one might initially expect, and that with some dedicated time, the learning curve is fast and rewarding.

In summary, what Plasman values most about Boards on Fire is how easy the system is to use, the clarity of its documentation, and its ability to create a uniform standard across the entire organization. The time savings are substantial, and the platform can easily be expanded as new needs arise.

Free web demo