Digital dashboards that help you identify deviations and make the right decisions.

Capture your deviations and turn them into improvements

Continuous improvement, Kaizen boards, PDCA and other tools.

Improve key performance indicators within your specific focus areas with our SQCDP board.

Use the PDCA cycle as a tool to improve both quality and processes

Digital tools for 5S work, recurring audits, and a well-organized workplace.

Visualize KPIs and communicate effectively throughout the entire organization.

Basic project management and activity boards.

Digital dashboards for takt time flow with takt time counter and stop time log.

Digital visitor registration provides full control over all planned and executed visits to your business.

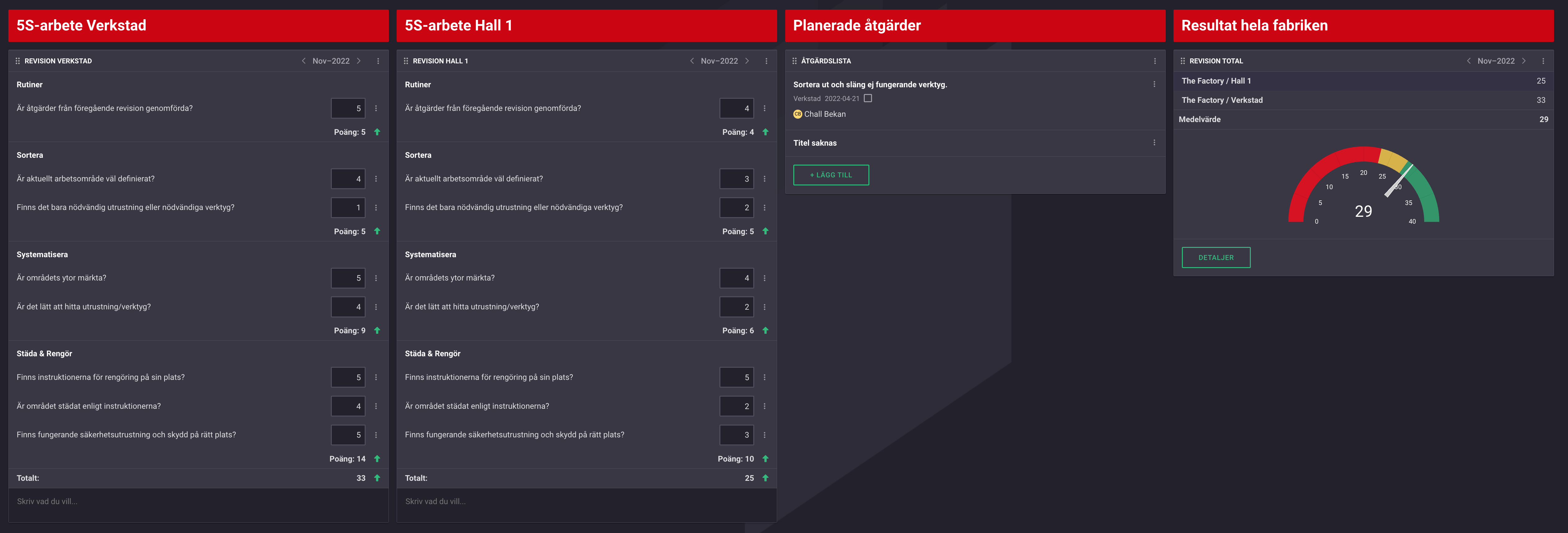

Improve the work environment by systematically clearing out, sorting, cleaning, standardizing, and maintaining the workplace. In Boards on Fire, you create dashboards to structure the 5S work for all areas in the business. Book a demo, and we'll show you how!

5S is a methodology for creating a structured, spacious, and clean workplace. It's about creating a common standard for how things should be organized and kept in place, making it easy to find what you need and ensuring the workplace is well-maintained. With Boards on Fire, you get digital tools that help you start your 5S work step by step in all areas. You can create customized checklists that make it easy to carry out regular 5S audits to check progress throughout the company. And you have a solid foundation for discussing results and finding suitable improvements for each area.

Free web demo

In Boards on Fire, it's simple to create checklists for regular audits of areas covered by 5S work. Using such a checklist, you can gain insights into areas that need improvement and help identify best practices that can then be shared across other departments or workstations. After each audit, results should be reviewed with the team, and plans made to address identified shortcomings.

Here we have listed an example of how questions for each "S" in such a checklist might look. The fulfillment of each question in the given area might be assessed on a scale of 1-5. Then, you can track the progress month by month in each area, but also cumulatively for an entire department or even an entire factory.

Feedback/comments:

Feedback/comments:

Feedback/comments:

Feedback/comments:

Feedback/comments: