Digital dashboards that help you identify deviations and make the right decisions.

Capture your deviations and turn them into improvements

Continuous improvement, Kaizen boards, PDCA and other tools.

All your team’s tasks, neatly organized in one weekly view.

Improve key performance indicators within your specific focus areas with our SQCDP board.

Use the PDCA cycle as a tool to improve both quality and processes

Digital tools for 5S work, recurring audits, and a well-organized workplace.

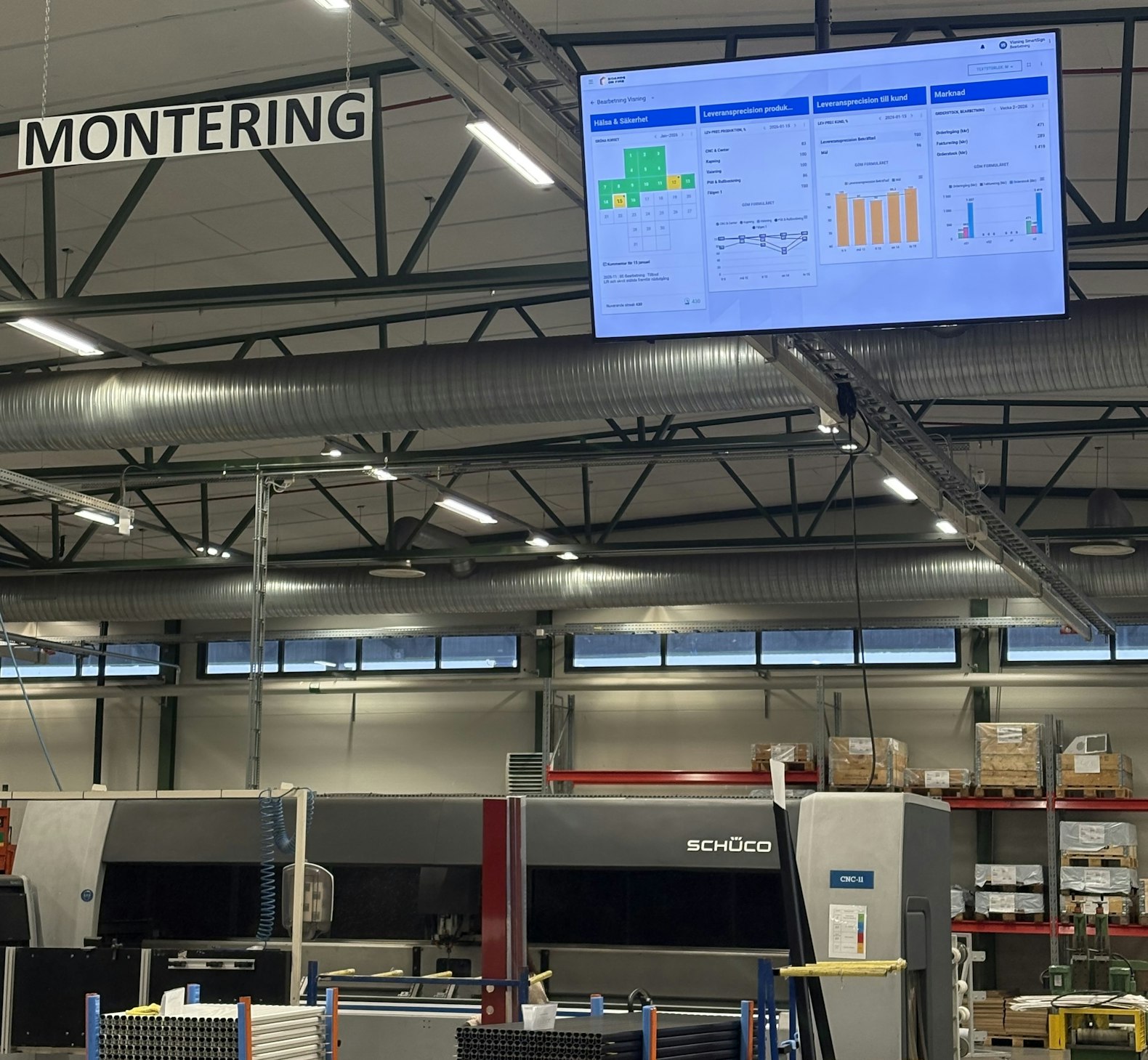

Visualize KPIs and communicate effectively throughout the entire organization.

Basic project management and activity boards.

Kanban is a powerful method for visualizing, managing, and optimizing workflows.

Digital dashboards for takt time flow with takt time counter and stop time log.

Digital visitor registration provides full control over all planned and executed visits to your business.

What happens when a company with decades of experience dares to challenge its established ways of working?

For A-Lackering, the answer was clear: improved visibility, stronger engagement, and more than 350 implemented improvements in a single year. The journey began back in the 1960s in Vårby, just outside Stockholm, where a local operation laid the foundation for what is today one of the Nordic region’s leading specialists in powder coating aluminium profiles.

The relocation to Sävsjö in 1997 marked the beginning of a new phase in A-Lackering’s development. Here, the company continued to strengthen its position by combining extensive experience with modern technology and a strong focus on quality. With around 180 employees and specialist expertise in both surface treatment and aluminium processing, A-Lackering today offers fully integrated solutions where the entire production chain is seamlessly connected.

At the same time, growth brought new challenges. Daily operations management, which had previously worked well, needed to evolve as more processes, departments, and KPIs had to be monitored in parallel. It became increasingly clear that the manual way of working no longer provided a sufficiently comprehensive view of production.

It was at this stage that Boards on Fire’s digital solution for daily management entered the picture. Since its implementation, the results have been clear:

Let’s now rewind and follow A-Lackering’s journey from analog to digital daily management.

For many years, A-Lackering’s daily management was built around a traditional approach, with large whiteboards serving as the hub for all planning and follow-up. The boards were often filled with performance figures, staffing allocations by department, and a limited set of key metrics, everything written and updated by hand.

Despite production managers and shop-floor teams doing their utmost to keep track of flows, resources, and results, the shared understanding of production history, current status, and future needs was limited. Decisions were often based on assumptions rather than complete data, increasing the risk of sub-optimisation and causing improvement opportunities to be missed. Small but important details could easily fall through the cracks, and communication between departments required extra effort to ensure everyone stayed aligned.

When A-Lackering’s CEO, Ola Bjelkvik, first learned about Boards on Fire’s digital solution for daily management through industry contacts, his curiosity was immediately sparked. Following recommendations from the Boards on Fire support team, the company started with a pilot in a single department. This made it possible to test the system in practice, see the benefits on a small scale, and evaluate the new way of working, without changing processes across the entire factory at once.

Once the first department began using Boards on Fire, the difference quickly became clear. The digital performance boards gave the team an immediate and transparent overview of production, while continuous improvement work gained a completely new structure. Small ideas and initiatives could now be logged, tracked, and measured in real time. The results were quick to follow, and it did not take long before management decided to roll out the solution to additional departments.

– At first, it felt a bit unusual that only one department was using Boards on Fire while the rest continued with the old routines. But once we saw how much easier everything became, there was no doubt we wanted to continue, says Ola Bjelkvik.

Today, Boards on Fire is used far beyond the walls of production. The marketing department conducts its pulse meetings in the system and at the same time has full visibility into what is happening on the shop floor. This has created closer collaboration between departments, better coordination, and a shared understanding of current status, priorities, and goals—regardless of role or function within the organisation.

The introduction of Boards on Fire has changed far more than just the numbers. Pulse meetings, which previously could be lengthy and difficult to follow, have become significantly more efficient and focused. Teams can now view exactly the same information in real time, making discussions more concrete and decisions faster.

Selected key metrics, ranging from production rate and staffing to quality and delivery precision—are displayed on more than 15 screens throughout the factory. This ensures that everyone works from the same, up-to-date picture of reality. There is no longer a need to collect information from multiple sources or double-check figures. Everything is centralised, visible, and continuously updated, contributing to greater transparency, faster decision-making, and a shared understanding of how production truly operates.

Boards on Fire has also delivered several measurable results. During 2025, for example, the company recorded zero lost-time accidents, delivery precision reached record levels, and employee satisfaction hit new highs. The teams have embraced the change with enthusiasm. Continuous improvement has become a natural part of everyday work, and during 2025 the company implemented more than 350 improvements directly in Boards on Fire.

– Previously, we used Excel for our improvement logs. In 2025 alone, we registered, tracked, and archived over 350 improvements directly in Boards on Fire. We can immediately see which ideas are making a real difference, Ola explains.

– Boards on Fire is not just a system, it represents a positive shift in how we view and manage our operations, summarises Anders Freding.

With the platform firmly in place, the company sees strong potential to further develop its way of working and continue building a culture where improvements and ideas are captured and acted on immediately. Support from Boards on Fire has been consistent and customer-focused, even when contact persons have changed.

What began as a pilot in a single department has grown into a tool that gives the entire organisation a shared direction, clearer decision-making, and more engaged employees.

Free web demo